News

Industrial nylon conveyor belts are critical equipment in automated production lines. Their speed and stability significantly impact overall efficiency. However, in actual use, slow conveyor belt speeds frequently occur, severely impacting production schedules and efficiency.

Typically, the speed of a conveyor belt can be adjusted by adjusting the motor speed. The speed can be adjusted based on production needs and material handling requirements. Some conveyor belts are also equipped with a speed regulator, which allows for manual or automatic speed control.

In industrial nylon conveyor belt systems, a belt cleaning system is a crucial component. A well-designed cleaning system ensures smooth conveyor belt operation, reduces impurities, and minimizes scratches caused by residual material or impurities.

As a benchmark for rubber industry manufacturing in Northeast China, Liaoning Hengyi successfully held employee skills training. Employee training is not only a routine part of human resource management, but also a core strategy to drive the sustainable development of the company. This training aims to help employees master cutting-edge industry knowledge, enhance core competitiveness, and inject new impetus into high-quality social development.

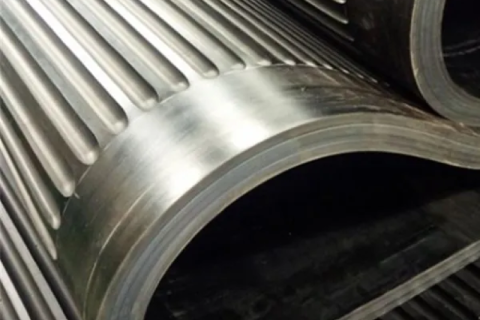

The rapid development of heavy industry worldwide has made material transportation a major challenge, and the demand for Nylon industrial conveyor belts has continued to rise. The demand for industrial conveyor belts is particularly high in industries such as mining, metallurgy, power generation, building materials, and chemicals. The corrosion- and wear-resistant properties of nylon industrial conveyor belts effectively improve efficiency and safety in production environments.

The core competitiveness of Hengyi conveyor belts stems from continuous investment in technology. In the context of industrial production, conveyor belts are like arteries in our body, carrying the flow of materials and improving efficiency. Liaoning Hengyi conveyor Belt Manufacturing Company has been deeply involved in the industry for more than 15 years, and has always regarded the deep cultivation of technology as the foundation of its existence.

During belt conveyor operation, some material or dust inevitably adheres to the conveyor belt surface. If the unloading device cannot completely remove the material, a conveyor belt cleaner is needed to remove this adhered material.

The Industrial Pattern Conveyor Belt is a specialized conveyor belt specifically designed for use in industrial material handling scenarios. Through the raised pattern structure, such as V-shaped,herringbone, wave, etc., the friction of the belt surface is significantly improved, which is designed to solve industry problems such as large inclination conveying, slippery material adhesion, and high wear environment.

The surface of the vacuum rubber filtration conveyor belt is a row of transverse grooves, and there are one or more rows of drainage holes in the grooves, and the drainage hole section can be made of pure glue; The skeleton layer of the belt body is made of high-strength polyester canvas or ribbon canvas; The upper and lower covering rubber of the filter belt can adopt different formulas according to the working conditions to meet different needs such as acid and alkali resistance, heat resistance, oil resistance, and cold resistance. The forming and vulcanization of the tape adopts a one-time integral compounding process to ensure the flatness of the tape body and the stability of performance.