News

Troughing idlers are found in most mining conveyor systems. They shape the belt into a trough. This shape helps carry lots of heavy material like coal or ore. The trough keeps things from falling off the belt. It also helps everything move without problems. The belt gets more support, so it does not break as much.

You can make mining work faster and safer with the right heavy industry conveyor belt idler. New idler systems help mining companies save money and lower accidents. For example, AI-based monitoring systems have stopped 27% of sudden idler failures. They also make the machines last 15% longer. Sensors help your conveyor work well, so you spend less on repairs and stay safer. Picking the right idler for your mine, like new designs such as Hengyi’s horn-shaped roller, helps move materials safely and quickly.

You want a conveyor system that runs smoothly with minimal downtime. Modern conveyor belt idlers now include several low-maintenance features that make your job easier. Manufacturers have moved external wear liners outside skirtboards. This change lets you inspect and replace liners quickly, without dismantling the system. You spend less time on maintenance and reduce the risk of unexpected failures.

You need to consider several criteria when choosing the best conveyor belt idler for your application. Start by checking technical specifications. Look for details like roller diameter, bearing type, seal type, and load ratings. Make sure your choice meets industry compliance requirements, such as CEMA for general use, MSHA for mining, or FDA for food processing.

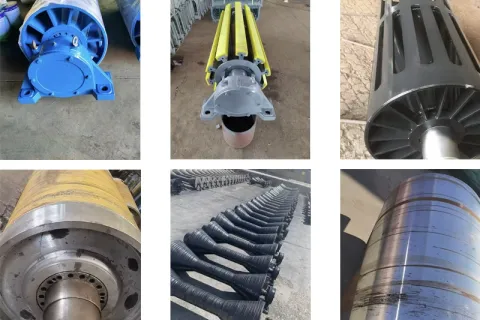

Comparing Conveyor Belt Idler Types: You face several choices when selecting an idler for your conveyor system. Each type serves a unique purpose and fits specific application needs. Troughing idlers help maintain the shape of the conveyor belt, which keeps materials secure and reduces spillage. You use impact idlers in loading zones where materials drop onto the belt. These Conveyor Belt Idler's absorb shock and prevent damage to both the belt

What Is a Conveyor Belt Idler You will find a conveyor belt idler as a key component in any conveyor system. It consists of a series of rollers mounted on a frame. Types of Conveyor Belt Idlers: You will encounter several types of conveyor belt idlers in industrial applications. Each type serves a specific purpose and fits different parts of the conveyor system.

Pick a heavy duty rubber conveyor belt when you need strength and long life. These belts are best for moving heavy or rough things. Here are some main ways people use them:

You need something that works for hard jobs. Heavy duty rubber conveyor belt technology is known for being tough and working well in places like mines and factories.

We will deepen and differentiate the article from the following dimensions to make it a truly technical industry guide:

A chevron rubber belt is a conveying product featuring a special herringbone pattern on its surface. Compared to ordinary flat conveyor belts, its greatest advantages lie in its anti-slip and high-angle conveying performance. Therefore, it is widely used for the continuous transport of bulk, bulk, and bagged materials. As a key component in industrial production systems, chevron rubber belts play a vital role in improving conveying efficiency, ensuring operational safety, and reducing maintenance costs in industries such as mining, building materials production, grain transportation, and ports.