Professional Analysis of Chevron Rubber Belts

2025-10-01 13:07I. Introduction.

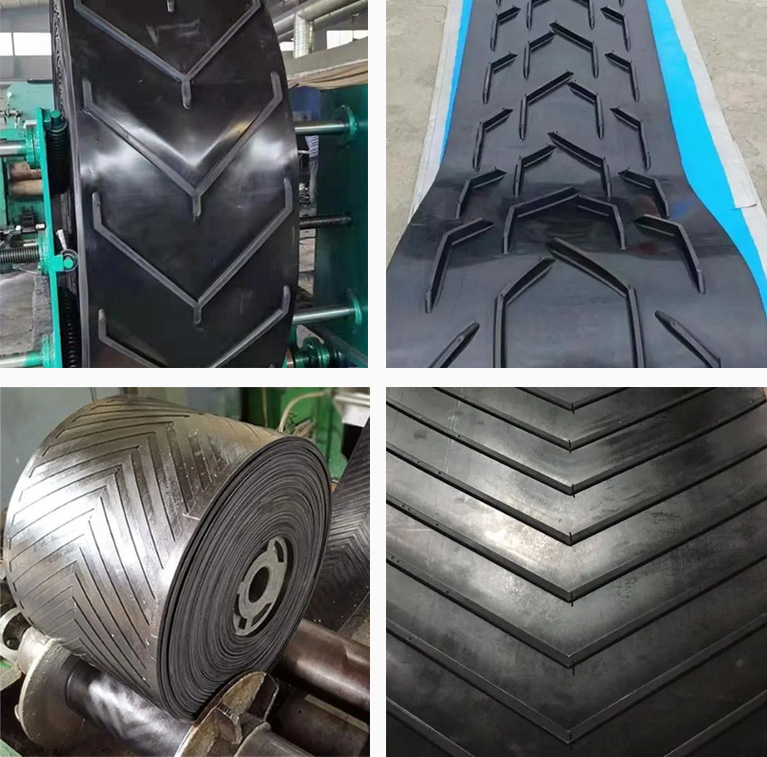

A chevron rubber belt is a conveying product featuring a special herringbone pattern on its surface. Compared to ordinary flat conveyor belts, its greatest advantages lie in its anti-slip and high-angle conveying performance. Therefore, it is widely used for the continuous transport of bulk, bulk, and bagged materials. As a key component in industrial production systems, chevron rubber belts play a vital role in improving conveying efficiency, ensuring operational safety, and reducing maintenance costs in industries such as mining, building materials production, grain transportation, and ports.

II. Product Features.

1. Pattern Design and Function.

The geometric structure of the chevron rubber belt pattern significantly enhances friction between the conveyor belt and the material, effectively preventing it from slipping during transport. Depending on the conveying angle, the herringbone pattern height and angle can be categorized as low, medium, and high to accommodate conveying angles ranging from 0° to 40°. Furthermore, the herringbone pattern can guide and disperse materials in concentrated areas, ensuring a smoother conveying process.

2. Material Advantages.

The rubber covering of Chevron rubber belts typically features different formulations for wear resistance, heat resistance, oil resistance, or cold resistance to cope with complex operating environments. For example:

· Wear-resistant: Suitable for high-friction materials such as ore and coal;

· Heat-resistant: Ensures the rubber surface does not crack when conveying high-temperature materials such as clinker, cement, and castings;

· Oil-resistant: Prevents oily materials from penetrating and causing the rubber surface to swell;

· Cold-resistant: Suitable for grain transportation and port operations in sub-zero environments.

This specialized rubber compound ensures that conveyor belts maintain stable physical properties and a long service life even under extreme operating conditions (open-pit and heavy industrial operations).

III. Main Application Scenarios.

1. Mining.

In coal, metal, and non-metallic mining, ore and coal must be transported from the extraction point to the crushing or storage and transportation stages. Chevron rubber belts, with their strong anti-slip properties and high load-bearing capacity, are ideal for conveying at steep angles and over long distances.

2. Building Materials Transportation.

Cement clinker, limestone, and sand and gravel aggregates often require high-temperature, high-volume transportation in construction material production. Heat-resistant Chevron rubber belts ensure continuous and stable operation in operating conditions ranging from 120°C to 150°C, effectively preventing material backflow.

3. Agriculture and Grain Processing.

In grain storage, feed processing, and agricultural product sorting, Chevron rubber belts are commonly used to transport bulk grain, potatoes, sugar beets, and other materials. Their anti-slip properties prevent material accumulation and improve conveying efficiency.

4. Ports, Terminals, and Logistics.

In the loading and unloading of bagged materials such as cement, fertilizer, and feed, Chevron rubber belts enable fast and safe loading and unloading, reducing manual intervention and improving efficiency.

5. Typical Use Cases.

A large cement group uses a heat-resistant herringbone conveyor belt in high-temperature environments, achieving a conveying angle of 30° and an average annual operating time of over 5,000 hours. The belt maintains excellent belt stability, significantly reducing equipment maintenance costs.

IV. Technical Parameters and Selection Recommendations.

1. Tread Type and Height.

Low Tread (5-10mm): Suitable for light-duty, low-angle conveying.

Medium Tread (10-15mm): Suitable for most common inclination angles (15°-25°).

High Tread (15-25mm): Suitable for high-inclination angles (30°-40°), requiring extremely high anti-slip properties.

2. Rubber Properties.

The rubber's tensile strength, elongation, abrasion resistance, and aging resistance should be selected based on the physical and chemical properties of the material being conveyed. For example, heat-resistant rubber should meet ISO 4195 standards.

3. Belt Structure.

Fabric Core: Nylon (NN) or Polyester (EP), offering excellent flexibility and impact resistance.

Steel Cord Core: Suitable for long-distance, high-volume, and high-intensity conveying, with a tensile strength exceeding 2000N/mm.

4. Selection Principles.

Factors such as conveying angle, material density, particle size, ambient operating temperature, conveying length, and drive power must be comprehensively considered to ensure that the performance of the Chevron rubber belt is compatible with actual operating conditions.

V. Installation and Maintenance.

1. Installation Precautions.

During installation, ensure that the Chevron rubber belt does not fold or twist. The tension must be properly adjusted to prevent premature damage.

2. Daily Maintenance.

Regularly inspect the conveyor belt for deviation, slack, and rubber wear.

Maintain a clean conveying environment to avoid scratches from sharp objects.

Check the matching of the pulley diameter and tread height to prevent excessive wear.

3. Common Faults and Solutions.

Deviation: Adjust the idlers or tensioning device.

Local damage: Repair with hot vulcanization or cold bonding.

Slippage: Check the tension or the condition of the drive pulley rubber cover.

VI. Product Upgrades and Innovations.

1. Application of New Materials.

In recent years, the gradual introduction of new materials such as aramid fiber-reinforced cores and nano-modified rubber has significantly improved the tear resistance and durability of conveyor belts.

2. Intelligent Monitoring and Maintenance Technology.

Online monitoring systems can collect real-time conveyor belt operating data, such as temperature, tension, and deviation, providing early warning of potential risks and significantly reducing unplanned downtime.

3. Environmental Protection and Sustainable Development.

The industry is gradually promoting green production, adopting low-VOC environmentally friendly rubber compounds, and increasing the recycling and regeneration of used conveyor belts, in line with sustainable development trends.

With its unique pattern design and excellent physical properties, Chevron rubber belts play an irreplaceable role in various industries, including mining, building materials, agriculture, and logistics. They not only improve conveying efficiency and operational safety, but also reduce maintenance costs. With the continuous development of new materials and intelligent technologies, future herringbone conveyor belts will continue to evolve towards high performance, long life, and environmental friendliness, providing more efficient and reliable solutions for industrial conveying systems worldwide.