Operational Demands of Conveyor System

2025-10-08 16:06Operational Demands

You should also look at how your conveyor operates day to day. The number of hours it runs, the frequency of loading, and the environment all affect your idler choice. Here are some key factors to consider:

1. Load capacity: Make sure your idlers can support the heaviest loads your system will carry. This affects the size of the rollers and the type of bearings you need.

2. Belt speed: Faster belts need idlers that reduce friction and heat. Choose idlers with the right bearings and roller materials for high-speed systems.

3. Environmental conditions: If your conveyor runs in harsh environments, pick idlers made from durable materials with sealed bearings.

4. Material type: The nature of your product—whether it is abrasive, sticky, or wet—will influence your idler specifications.

5. Selecting the right conveyor belt idler for your system means matching these requirements to your application. This ensures reliable performance and longer equipment life.

Load and Speed Factors

Load Capacity

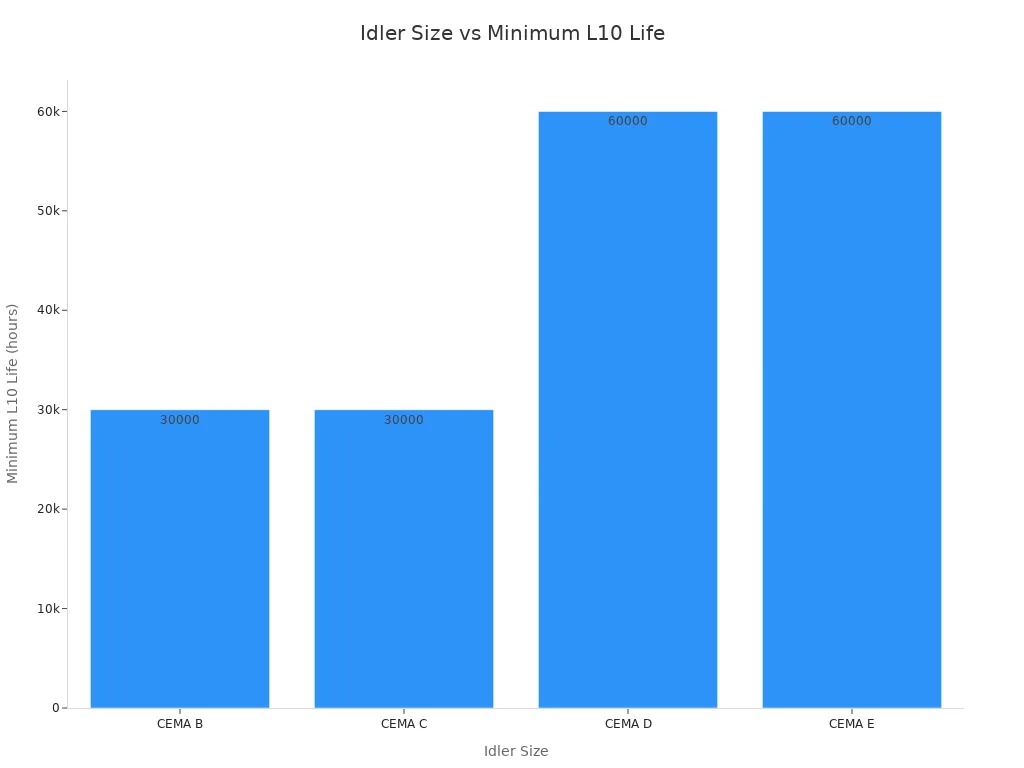

You need to match the idler size and roll diameter to your system’s load. The right choice ensures your conveyor runs safely and efficiently. Manufacturers rate idlers by their load capacity and expected lifespan. The table below shows typical ratings for different idler sizes:

Idler Size | Minimum L10 Life (hours) | Load Rating (rpm) |

|---|---|---|

CEMA B | 30,000 | 500 |

CEMA C | 30,000 | 500 |

CEMA D | 60,000 | 500 |

CEMA E | 60,000 | 500 |

Larger idlers, such as CEMA D and E, support heavier loads and offer longer service life. Smaller idlers, like CEMA B and C, work well for lighter applications. If you choose an idler that is too small, you risk early failure and more frequent maintenance. If you select an idler that is too large, you may increase costs without added benefit.

Tip: Always check your system’s maximum load before selecting an idler size. This step helps you avoid costly breakdowns.

Belt Width and Speed

Belt width and speed play a big role in idler selection. Wider belts carry more material, which increases the load on each idler. Faster belt speeds, which can range from 7.5 to 11.5 meters per second, create more friction and heat. These factors can lead to faster wear and more dust. You need to choose idlers that match both the width and speed of your belt to keep your system running smoothly.

If you use a narrow belt with slow speed, smaller idlers may work well. For wide or high-speed belts, you should select larger idlers with high-quality bearings. This choice helps control dust, reduce material degradation, and extend the life of your conveyor.

Static vs. Dynamic Loads

You must consider both static and dynamic loads when choosing idlers. Static loads include the weight of the belt and the material it carries. Dynamic loads involve forces that change as the conveyor operates. These include impact from loading, vibrations, and uneven rotation.

· Static loads focus on the weight of the material and the conveyor belt.

· Dynamic loads include factors such as eccentric rotation, impact loads, and lateral vibrations.

· Accurate calculations of both load types are essential for safe and efficient conveyor operation.

1. Traditional designs prioritize static load calculations.

2. Dynamic analysis is increasingly important in modern conveyor systems.

3. Load distribution among idlers is critical, especially in curved sections.

If you ignore dynamic loads, you may see unexpected wear or even system failure. You should always calculate both load types to ensure your conveyor belt idler performs reliably.

Operating Conditions

When you select a conveyor belt idler, you must consider the environment where your system operates. Environmental factors can affect the performance, durability, and lifespan of your equipment. You need to choose materials and designs that can handle these challenges.

Environmental Factors

Dust and Moisture

Dust and moisture often cause problems in conveyor systems. Dust can build up on rollers and bearings, leading to extra wear and possible failure. Moisture can weaken the material of the idler and the belt. High humidity encourages rust on metal parts, which shortens the life of your equipment.

· Humidity and moisture can weaken the material of conveyor belts.

· High humidity encourages rusting of metal components.

· Regular inspections are necessary to manage moisture buildup.

You should look for idlers with sealed bearings and corrosion-resistant coatings. These features help keep dust and water out, which protects the moving parts. You also need to schedule regular cleaning and maintenance to prevent buildup.

Corrosive Elements

Some environments expose your conveyor system to chemicals or corrosive substances. Even small amounts of these substances can erode crucial components over time. Corrosive damage often leads to unexpected breakdowns and costly repairs.

· Corrosive substances can erode crucial components over time.

· Even small amounts can lead to significant damage.

· Regular maintenance checks are essential to avoid costly repairs.

You can choose idlers made from special materials like ceramic or nylon. These materials resist corrosion and last longer in harsh conditions. You should also use specialized coatings for extra protection.

Temperature Extremes

Temperature changes can affect how your conveyor belt idler works. Extreme heat can cause materials to expand or soften, while cold can make them brittle. You need to select idlers that match the temperature range of your facility.

Environmental Factor | Description |

|---|---|

Temperature | Must be suitable for the specific operating conditions. |

Humidity | Affects the performance and durability of the idler. |

Chemical Exposure | Can erode components and lead to failure if not managed. |

You should always check the manufacturer’s temperature ratings before making your choice.

Indoor vs. Outdoor Use

Indoor and outdoor environments create different challenges for conveyor systems. Indoor systems usually face less moisture and fewer temperature swings. Outdoor systems must handle rain, sun, wind, and sometimes chemicals from nearby processes.

Type of Idler | Key Features | Suitable Conditions |

|---|---|---|

Ceramic Idler | Wear resistance, acid/alkali resistance, oxidation resistance, high strength | Harsh outdoor environments |

Nylon Idler | Low friction, abrasion resistance, excellent self-lubricity | Harsh environmental conditions |

Impact Idler | High toughness, corrosion resistance, flame retardant | Corrosive environments (e.g., mining) |

You should select idlers with durable materials, specialized coatings, and sealed bearings for outdoor use. These features help your system resist weather and chemical exposure. For indoor use, you can focus more on efficiency and noise reduction.

Tip: Always match your idler’s material and design to your operating environment. This step helps you avoid early failures and keeps your conveyor running smoothly.

Conveyor Belt Idler Selection

Comparing Conveyor Belt Idler Types

You face several choices when selecting an idler for your conveyor system. Each type serves a unique purpose and fits specific application needs. Troughing idlers help maintain the shape of the conveyor belt, which keeps materials secure and reduces spillage. You use impact idlers in loading zones where materials drop onto the belt. These Conveyor Belt Idler's absorb shock and prevent damage to both the belt and the frame. Return idlers support the belt on its return path, stopping sagging and extending the belt’s service life. Specialized idlers, such as training return idlers, correct misalignment and ensure smooth operation.

Idler Type | Application Suitability |

|---|---|

Troughing Idlers | Ideal for transporting materials securely, maintaining load-bearing capacity, and minimizing spillage. |

Impact Idlers | Designed for loading areas to absorb impact forces and prevent damage to the belt and surrounding structure. |

Return Idlers | Used on the return side to support the belt, preventing stretching and sagging, thus increasing service life. |

Specialized Idlers | Tailored for specific applications, such as training return idlers that correct belt misalignment. |

Tip: Always match the idler type to the specific section of your conveyor system. This step helps you avoid unnecessary wear and keeps your operation running smoothly.