- Home

- >

News

You should think about the total cost, not just the price. The total cost of ownership (TCO) means what you pay at first, to run the belt, and to fix it. Here is a simple table:

You should pick the right type and material for your bucket conveyor belt. This helps you get the best results in 2025. Look at what product you want to move. Think about where the belt will be used. Also, think about how much you need it to work well. Some people choose thin materials or forget digger buckets. These mistakes can make the belt break or cost more to fix. Think about these things first so you do not have big problems later.

You notice a clear difference when you compare a Steep Angle Sidewall Conveyor Belt to a standard conveyor system. The sidewall design lets you move materials up very steep angles, even close to vertical, while saving space. You can boost your throughput in tight areas without worrying about spillage or loss of control. This system works where traditional conveyors cannot, giving you more flexibility and efficiency.

You want your mine to be better for the earth. Sustainability changes how you pick and use conveyor belt idlers. Many companies use recycled materials and bio-based polymers now. This helps lower harm to the environment. It also helps you follow new rules and show you care about the planet.

Stopping work by surprise costs a lot of money. New idler systems help you avoid this. Smart tools, like the Smart-Idler® system, watch your conveyor’s health. They warn you before something breaks. Big mines use these tools to stop surprise breakdowns and save money.

The cost of a conveyor belt in 2025 usually falls between $30 and $100 per meter. Some units range from $1,570 to $5,060, while fabric belts can cost $10 to $50 per foot. You will see several factors influence these prices:

You can make mining work faster and safer with the right heavy industry conveyor belt idler. New idler systems help mining companies save money and lower accidents. For example, AI-based monitoring systems have stopped 27% of sudden idler failures. They also make the machines last 15% longer. Sensors help your conveyor work well, so you spend less on repairs and stay safer. Picking the right idler for your mine, like new designs such as Hengyi’s horn-shaped roller, helps move materials safely and quickly.

You want a conveyor system that runs smoothly with minimal downtime. Modern conveyor belt idlers now include several low-maintenance features that make your job easier. Manufacturers have moved external wear liners outside skirtboards. This change lets you inspect and replace liners quickly, without dismantling the system. You spend less time on maintenance and reduce the risk of unexpected failures.

You need to consider several criteria when choosing the best conveyor belt idler for your application. Start by checking technical specifications. Look for details like roller diameter, bearing type, seal type, and load ratings. Make sure your choice meets industry compliance requirements, such as CEMA for general use, MSHA for mining, or FDA for food processing.

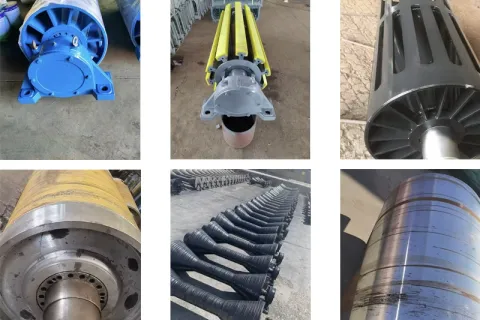

Comparing Conveyor Belt Idler Types: You face several choices when selecting an idler for your conveyor system. Each type serves a unique purpose and fits specific application needs. Troughing idlers help maintain the shape of the conveyor belt, which keeps materials secure and reduces spillage. You use impact idlers in loading zones where materials drop onto the belt. These Conveyor Belt Idler's absorb shock and prevent damage to both the belt

What Is a Conveyor Belt Idler You will find a conveyor belt idler as a key component in any conveyor system. It consists of a series of rollers mounted on a frame. Types of Conveyor Belt Idlers: You will encounter several types of conveyor belt idlers in industrial applications. Each type serves a specific purpose and fits different parts of the conveyor system.

Pick a heavy duty rubber conveyor belt when you need strength and long life. These belts are best for moving heavy or rough things. Here are some main ways people use them: