- Home

- >

- Products

- >

- Troughing Rolls

- >

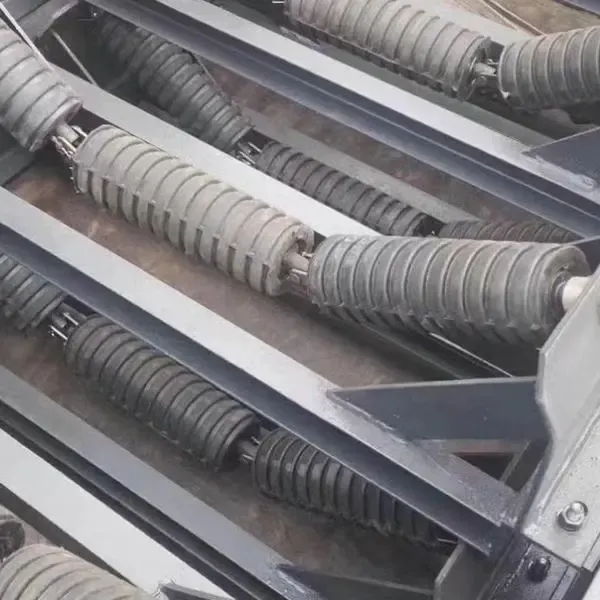

Troughing Rolls

1. The core components of trough idler rollers are made of high-quality sealed bearings and high-strength materials, which are durable and wear-resistant, corrosion-resistant, and can significantly extend the replacement cycle.

2. Trough idler rollers have undergone rigorous dynamic balance testing and can run smoothly at high speeds, effectively reducing material spilling and conveyor belt deviation.

3. The optimized structural design and high-precision sealing components greatly reduce the friction noise of trough idler rollers during operation and can improve the working environment.

- Hengyi

- Shenyang, Liaoning

- Depends on the actual situation

- 12 million ㎡ /year

- Information

In the fierce market competition, the stability and efficiency of the conveyor line operation will be directly related to your production costs and output. Choosing the right trough idler rollers is an important part of ensuring the smooth, efficient and low-cost operation of the entire conveying system. We are committed to providing B-side partners with a solid and reliable trough idler rollers solution.

Introduction of trough idler rollers:

The trough idler rollers we produce are an important part of the belt conveyor. Trough idler rollers are mainly used to support conveyor belts and material weight. We strictly control every process from raw materials to finished products, and the conveyor idler rollers produced have uniform wall thickness, high strength and strong load-bearing capacity.

Advantages of conveyor idler rollers:

1. Conveyor idler rollers have a longer service life and a lower failure rate, which can directly reduce your spare parts inventory and replacement maintenance costs.

2. Conveyor idler rollers adopts a low operating resistance design, which helps to reduce the driving power of the whole machine, and conveyor idler rollers can save you energy consumption.

3. The smooth operation of conveyor idler rollers and the effective support of the conveyor belt directly extend the service life of the higher-priced conveyor belt.

Signal that conveyor idler rollers is running abnormally:

1. During normal operation, return rollers for conveyors will only emit a uniform and slight rolling sound. If there is an intermittent abnormal sound, sharp friction sound or metal collision sound, it may be caused by bearing wear of return rollers for conveyors, internal stuck debris, or deformation of the pipe wall of return rollers for conveyors. It needs to be stopped in time for inspection.

2. Gently dial the stationary return rollers for conveyors by hand. Normally, they should be able to rotate smoothly for 2 to 3 laps. If the resistance is large during rotation, the caton is incoherent, or the partial return rollers for conveyors do not turn and only slip after starting, usually the bearing is out of oil, the seal is damaged and the dust enters, which will accelerate belt wear for a long time.

FAQ:

Q: How to ensure the stability and reliability of long-term cooperation?

A: We have a stable supply chain of raw materials and large-scale production lines, which can keep the quality of return rollers for conveyors consistent and ensure punctual delivery. Cooperating with us means that you have obtained a long-term, stable and reliable partner without worrying about supply chain breakages or quality fluctuations.

About us:

Our company was established in 2018 and passed IS0 9000 standard certification, IS0 9001 quality management system certification, IS0 14001 environmental management system and OHSAS 18001 occupational safety and health management system standard certification in 2021, and obtained AAA credit enterprise certification. Our company has complete testing methods, excellent domestic testing equipment and advanced production equipment.