- Home

- >

- Products

- >

- Head/Tail Pulley

- >

Head/Tail Pulley

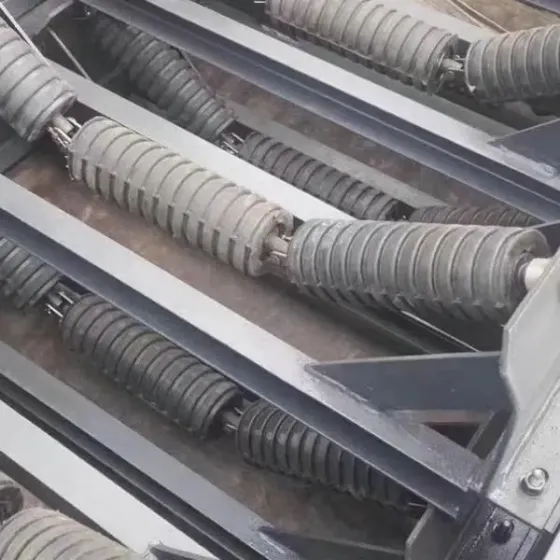

1. After precision machining and dynamic balance correction, conveyor pulleys operate smoothly and have a long service life.

2. The sealing performance of conveyor pulleys is excellent, which can effectively block the intrusion of dust and water vapor, and protect the normal operation of the bearing in harsh environments.

3. The scientifically designed bearing configuration and precise assembly process reduce the rotational resistance of conveyor pulleys, which can effectively reduce the energy consumption of the system.

- Hengyi

- Shenyang, Liaoning

- Depends on the actual situation

- Depends on the actual situation

- Information

In industrial conveying systems, conveyor pulleys are important components that can affect the operating efficiency of the entire line. According to statistics, about 35% of conveyor system failures are related to conveyor pulleys, and the downtime losses caused by frequent replacement of conveyor pulleys are usually several times the procurement cost. Our conveyor pulleys have established a complete quality system from material selection, process control to performance testing, and each conveyor pulleys can maintain stable operation under harsh operating conditions. Our conveyor pulleys have been widely used in electric power, mining, ports, building materials and other industries.

After actual verification, conveyor head pulley can help customers:

● Reduce equipment maintenance costs by about 40%.

● Reduce downtime due to conveyor head pulley failure by about 60%.

● Extend the service life of the conveyor belt by about 30%.

Introduction of conveyor head pulley:

Conveyor head pulley adopts a scientific pipe roller proportional design, and the pipe body is made of high-quality high-frequency welded pipe, which is precision machined to make the radial runout ≤0.5mm. The types and specifications of conveyor head pulleys we produce are complete, which can meet the needs of different working conditions and keep the conveyor belt on an ideal trajectory.

The value of conveyor head pulley:

1. The strictly controlled dynamic balance accuracy makes the operating vibration value of the conveyor head pulley lower than the industry standard, which effectively reduces operating noise and extends the service life of the bearing.

2. The precise manufacturing process allows the conveyor head pulley to run smoothly, effectively preventing the conveyor belt from deviating and improving the conveying efficiency.

3. Strict quality control makes the conveyor head pulley reliable and reduces unplanned downtime caused by the failure of the conveyor head drive wheel.

FAQ:

Q: How to evaluate the expected service life of the conveyor head drive wheel?

A: The service life of the conveyor head drive wheel depends on the operating environment, load conditions and maintenance level. Under standard operating conditions, the design life of our conveyor head drive wheel can reach 30,000 hours, and most customers feedback that the use time is more than 3 years in actual use.

Q: How to identify the quality of the conveyor head drive wheel when purchasing?

A: It is recommended to focus on the uniformity of pipe thickness, welding quality, rotation flexibility and sealing structure design of conveyor head drive wheel. We welcome customers to inspect our production process to prove our capabilities.

Our delivery:

As a professional supplier, our company understands the importance of logistics and freight for buyers' decision-making. We can provide flexible transportation methods according to the location of our customers, and choose suitable solutions according to the different needs of different customers. All our products will be professionally packaged before transportation. The use of packaging cloth materials that meet international standards, so that the products are not damaged by the external environment during long-distance transportation. For special specifications of products, we can provide customized packaging, and the specific details need to be communicated in detail by both parties.