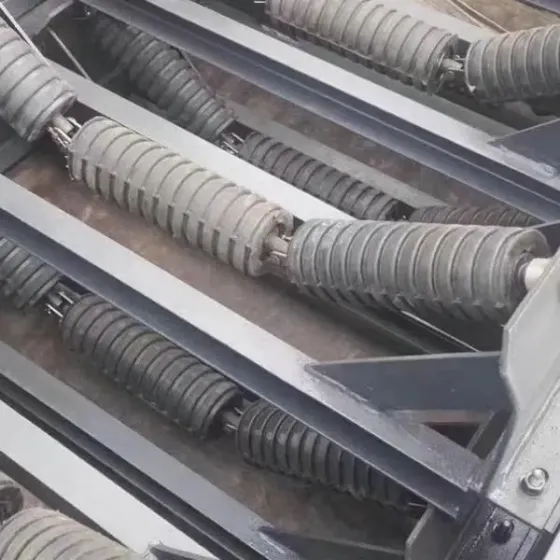

Rubber Conveyor Belt Rollers

1. Conveyor belt rollers use standard steel, with uniform tube thickness and strong carrying capacity.

2. Conveyor belt rollers are processed using professional equipment, which runs smoothly and has a long service life.

3. Conveyor belt rollers can be effectively dustproof and waterproof, and adapt to the needs of different working environments.

- Hengyi

- Shenyang, Liaoning

- Depends on the actual situation

- Depends on the actual situation

- Information

In industrial production, conveyor belt rollers are an important part of the conveying system, and its quality is directly related to the service life and operating costs of the equipment. The conveyor belt rollers we produce, through professional production technology and strict quality control, can provide reliable support for all kinds of industrial conveying systems.

We understand that as the person in charge of procurement, what you are most concerned about is:

● How to ensure that the quality of the purchased rubber conveyor belt rollers is stable and reliable.

● How to reduce the frequency and cost of equipment maintenance.

● How to find a long-term stable supplier partner.

This is exactly the problem we focus on solving. Through professional manufacturing and attentive service, we are committed to becoming your most reliable supplier of rubber conveyor belt rollers.

Introduction of rubber conveyor belt rollers:

Conveyor idler rollers are an important part of belt conveyors and play an important role in supporting conveyor belts and materials. The conveyor idler rollers we produce strictly follow the relevant standards and requirements, and every link is strictly controlled from the procurement of raw materials to the production and processing. Our conveyor idler rollers have complete specifications, which can meet the needs of different bandwidths and different operating conditions.

Advantages of conveyor idler rollers:

1. We adopt strict production technology and quality control, so that every conveyor idler rollers can exceed quality standards.

2. High-quality materials and professional manufacturing technology allow conveyor idler rollers to have a longer service life and effectively reduce the replacement frequency.

3. Through different processes, conveyor idler rollers can adapt to a variety of working environments. Whether it is indoor or outdoor, dry environment or humid working conditions, conveyor idler rollers can maintain good use results.

Typical cooperation case of rubber conveyor belt rollers:

1. Mining field: the rubber conveyor belt rollers of the customer's original conveyor system are severely worn out and replaced frequently. We provide customers with reinforced sealed rubber conveyor belt rollers, which significantly improves the operating rate of equipment and reduces the workload of maintenance personnel, and has been highly recognized by the customer's equipment management department.

2. Port scene: for the special environment of high salinity and high humidity, we provide customers with anticorrosive rubber conveyor belt rollers. Rubber conveyor belt rollers have withstood the test of harsh environments and their service life has been significantly extended, helping customers improve the operating conditions of their equipment.

3. Building materials industry: facing the needs of customers for cost reduction and efficiency enhancement, we have optimized the rubber-coated conveyor rollers configuration plan, which not only improves the stability of the conveying system, but also saves customers comprehensive operating costs and establishes a long-term stable cooperative relationship.

About us:

In the field of industrial transportation, the quality of rubber-coated conveyor rollers directly affects the operating efficiency and maintenance costs of production lines. As a professional manufacturer that has passed ISO 9001 quality management system, ISO 14001 environmental management system, OHSAS 18001 occupational safety and health management system certification, and won the title of AAA credit enterprise, we understand the importance of systematic management and standardized production to the quality of rubber-coated conveyor rollers. Based on the service experience of more than 300 companies, we recommend that the purchasing person in charge not only pay attention to the unit price of rubber-coated conveyor rollers when choosing suppliers, but also conduct a comprehensive assessment from the perspective of life cycle cost, quality stability and supply chain assurance. Our rubber-coated conveyor rollers are developed and manufactured based on this concept. At present, they have helped customers reduce maintenance costs by 25% to 30%, and the overall energy efficiency of the equipment has been increased by more than 15%. The actual benefits. When you are looking for not only products, but also a reliable conveying system solution, our professional team is always ready to provide you with one-stop service from selection to after-sales.