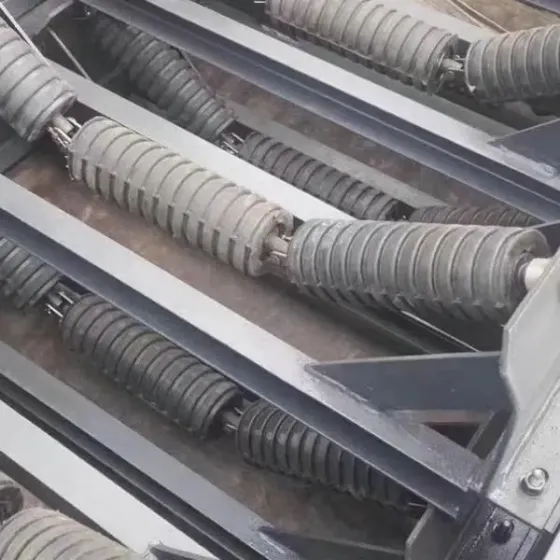

Stone Crusher Conveyor Rollers

1. Conveyor head rollers adopts high-quality high-frequency welded pipes, the wall thickness is uniform, the radial runout is controlled within the national standard range, and the operation is stable.

2. Conveyor head rollers have a strong carrying capacity and can adapt to different load requirements.

3. Each conveyor head rollers will undergo dynamic balance correction, which has low vibration and low noise during high-speed operation, which can protect the conveyor belt.

- Hengyi

- Shenyang, Liaoning

- Depends on the actual situation

- Depends on the actual situation

- Information

In the continuous operation of the conveying system, the performance of the conveyor head rollers will directly affect the efficiency of the entire production line. The deviation of the conveyor belt caused by an inferior conveyor head rollers may cost you thousands of yuan in output value per hour. The maintenance costs caused by frequent replacement of conveyor head rollers virtually harm your profits.

When your conveyor system has the following conditions, it is time to consider upgrading conveyor head rollers:

● The frequency of conveyor head rollers is changed more than once every six months.

● The conveyor belt has a continuous deviation phenomenon.

● The operating noise of the equipment has increased significantly.

● Energy consumption indicators are constantly rising.

Introduction of heavy-duty steel conveyor rollers:

Heavy-duty steel conveyor rollers are important components of belt conveyors. Heavy-duty steel conveyor rollers mainly play an important role in supporting the conveyor belt and material weight and ensuring the stable operation of the conveyor belt. The heavy-duty steel conveyor rollers we produce are designed and manufactured in strict accordance with international standards, covering multiple categories. Our heavy-duty steel conveyor rollers are made of high-quality steel pipes that have been precision machined, with high-performance bearings and advanced sealing technology, and can maintain excellent operating performance under heavy loads, high speeds, and harsh environments. Our heavy-duty conveyor belt rollers have complete specifications, which can meet the needs of different industries and different working conditions.

Advantages of heavy-duty conveyor belt rollers:

1. High-quality materials and precision manufacturing technology have improved the service life of heavy-duty conveyor belt rollers, greatly reducing the replacement frequency and spare parts inventory. In addition, heavy-duty conveyor belt rollers adopts a reliable sealing design, which reduces the need for lubrication and maintenance, and can reduce comprehensive maintenance costs.

2. Precise dynamic balance correction allows heavy-duty conveyor belt rollers to run smoothly, reducing conveyor belt deviation and material leakage, and improving conveying efficiency.

3. The excellent sealing performance allows heavy-duty conveyor belt rollers to maintain good operating conditions in harsh environments such as dust and humidity, reducing the possibility of unplanned downtime and ensuring production continuity.

FAQ:

Q: How to determine whether the existing steel idler rollers for conveyors need to be replaced in bulk?

A: When steel idler rollers for conveyors rotate inflexibly, the resistance to rotation by hand is obvious, the operating noise exceeds 85 decibels, the radial runout is greater than the national standard, and the surface corrosion is serious or there are wear grooves, steel idler rollers for conveyors need to be replaced in batches. If you have any questions, you can contact us at any time and we will help you evaluate the status of steel idler rollers for conveyors.

Q: How to evaluate the comprehensive strength of steel idler rollers for conveyors suppliers?

A: It is recommended to investigate the supplier's advanced production technology and equipment, quality inspection system and certification, raw material supply channels and quality control, and after-sales service and technical support capabilities.

Our delivery:

Now, in manufacturing companies, in addition to the quality of steel idler rollers for conveyors itself, logistics has become more and more important. The efficiency and reliability of logistics will directly affect production efficiency and customer experience. As a professional manufacturer, our company understands the importance of logistics and freight, so we have been committed to providing customers with efficient, safe and timely transportation security services. We work closely with a number of logistics companies to integrate resources and optimize transportation processes, so that each batch of products can be delivered to customers safely and accurately.