How Does the Chevron Convex Conveyor Belt Solve the Problem of Large Inclination Material Slipping?

2025-08-04 15:15When mining companies are faced with the constant problem of powder slippage on steep slopes, the material loss rate of up to 15% of traditional planar conveyor belts forces frequent line downtime to clean up – this is the opportunity for Chevron Convex Conveyor Belt to come into play. Chevron Convex Conveyor Belt is an industrial conveyor belt designed for inclined material conveying, its core feature is that the belt surface is in a continuous V-shape, by increasing friction to solve the problem of material slippage, is the key technical equipment to achieve large inclination, high efficiency and low loss conveying.

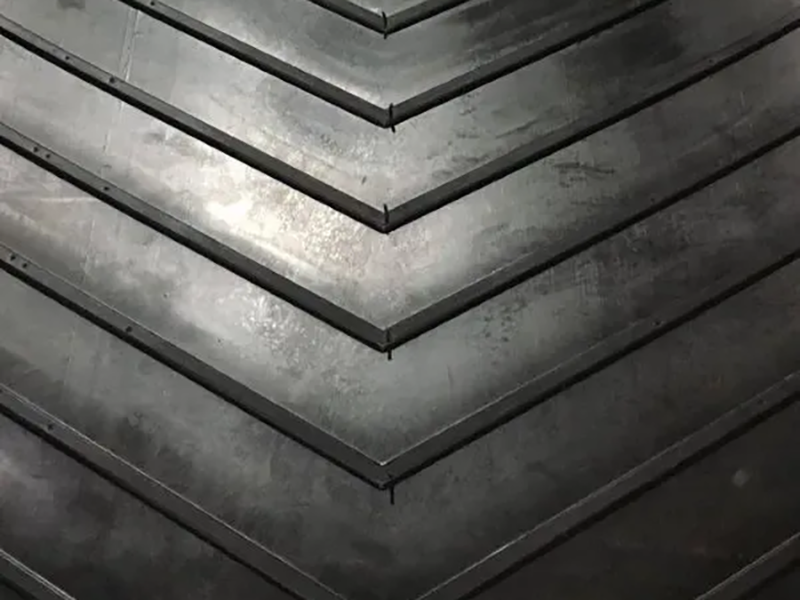

The Chevron Convex Conveyor Belt overcomes the problem of slipping materials with large inclinations, essentially subverting the traditional friction mechanism through sophisticated structural engineering. At its core, the band is arranged regularly on the surface, and these V-shaped or trapezoidal three-dimensional convex patterns run through the band like miniature ridges. When the conveyor belt is running at an inclined angle, the bevel of the convex is actively cut into the bottom of the material, so that the gravity of the load such as coal, ore or grain is broken down into two parts: the forward pressure of the vertical compression of the belt surface and the sliding force blocked by the side wall of the convex pattern. This mechanical chimerism effect is similar to a micro gear bite material, transforming sliding friction into more reliable static friction, completely reversing the passive situation of the material governed by gravity.

The fluid dynamic design targets the risk of collapse of wet viscous materials. The grooves between the convex lines form a high-efficiency diversion system, and when transporting clay or harbor salt ore with a water content of 15%, the V-shaped groove quickly directs the slurry water to the centerline and discharges. At the same time, the micro-negative pressure generated in the trench during high-speed operation has a gentle adsorption effect on wet materials, preventing slurry splashing accidents at a nickel ore transfer station in Indonesia. The actual measurement shows that in the sludge transportation at a 35° inclination angle, this design reduces the adhesion of wet materials by 82%, and solves the slip chain reaction caused by material compaction.

Our company's Chevron Convex Conveyor Belt is made of natural rubber, which has the advantages of wear resistance, scratch resistance, corrosion resistance, etc., which can solve the problem of material sliding during bulk material transportation, improve the efficiency of bulk material transportation, and overcome terrain restrictions. The company has excellent domestic testing equipment and advanced production equipment, with an annual output of 12 million square meters. If you want to buy high-quality, long-life conveyor belts, please feel free to contact us, we will be your most satisfied choice!