High-Performance Conveyor Belts: Enabling Efficient and Safe Operations in the Mining Industry

2025-09-30 15:12The mining industry faces extremely demanding production environments, placing extremely high demands on conveyor belt performance. Whether operating over long distances, handling heavy loads, or facing high wear and impact, reliable conveyor belts are crucial for ensuring production efficiency and safety. We specialize in providing customized conveyor belt solutions for mining companies, helping them maximize equipment uptime and economic efficiency. Our product offering includes both conventional conveyor belts and specialized conveyor belts for specialized applications.

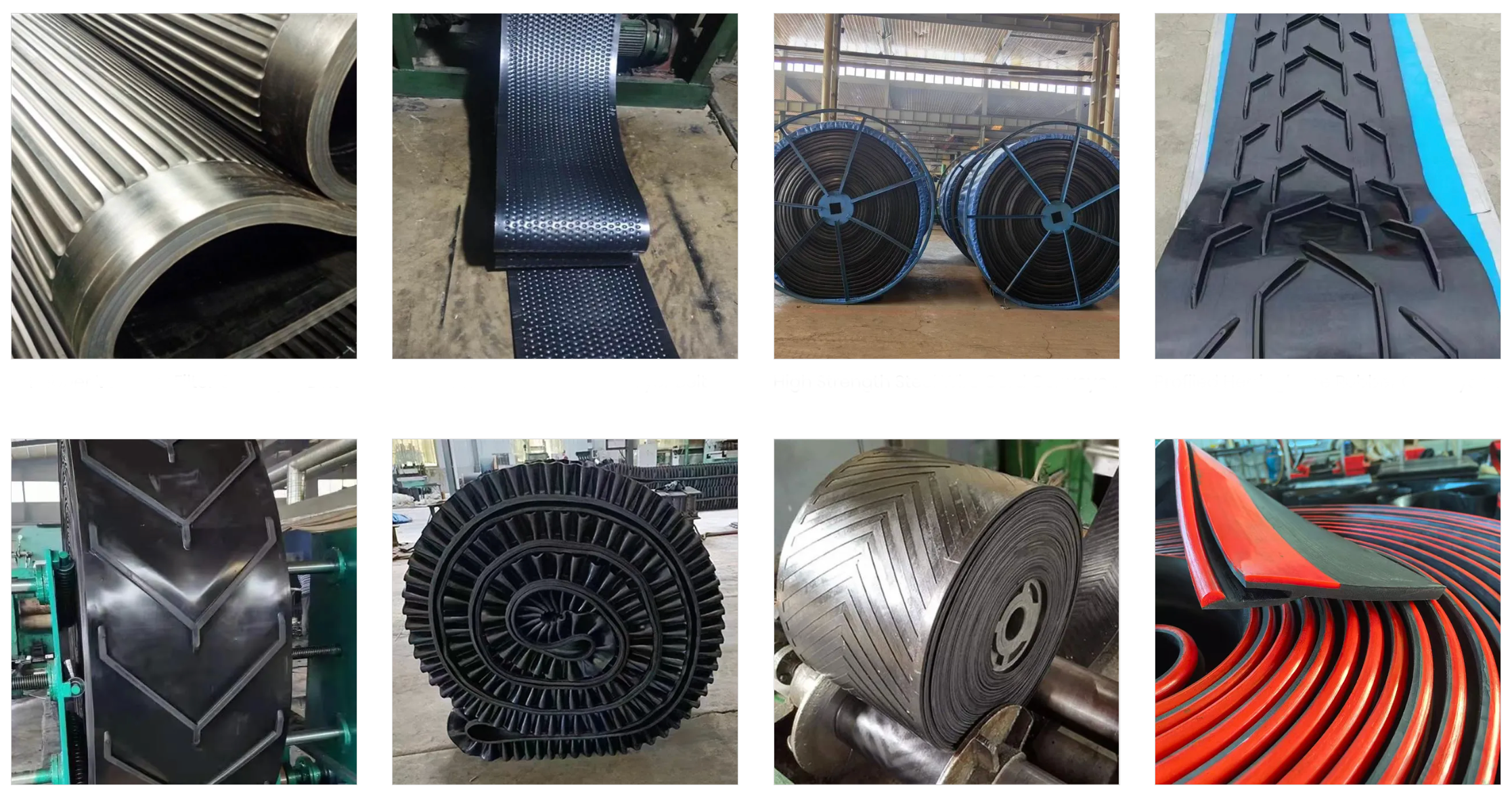

We offer the following types of conveyor belts for the mining industry:

- Steel Cord Conveyor Belts:

Offering exceptional strength, flexibility, and impact and tear resistance, they are suitable for large-scale mines and bulk material transport, especially for long-distance, high-load conveying. A variety of cover rubber options are available to meet diverse requirements, including wear resistance, low-temperature resistance, impact resistance, heat aging resistance, ozone resistance, flame retardancy, and self-extinguishing properties.

- Fabric Conveyor Belts:

Highly flexible, suitable for medium loads, short-distance conveying with frequent curves, and adaptable to diverse site layouts. - Herringbone Conveyor Belts: Designed for inclined transport, they can accommodate slopes up to 45°. Available in a variety of patterns and performance options, including special qualities like heat and grease resistance, they meet individual customer needs.

- Straight Warp Conveyor Belts:

Suitable for open-pit mines, they offer low maintenance, low permanent elongation, and strong impact resistance. Compared to traditional multi-layer fabric conveyor belts, straight warp belts are thinner and lighter, significantly saving energy, and are suitable for small-diameter pulleys.

- Conveyor Belts with Break Protection Layers:

Designed for transporting high-altitude materials, hard or bulky materials prone to perforation and tearing, these belts feature fabric or steel wire break protection layers to effectively extend belt life. Customizable wire diameters, spacing, and rubber grades are available.

We offer a variety of rubber materials:

- Wear-Resistant Rubber:

Suitable for a variety of high-intensity working environments and highly abrasive materials. Available in standard grades such as DIN X, Y, and W, and ISO H, D, and L, with customizable high-performance composite grades. - Flame-retardant and self-extinguishing rubber: We offer flame-retardant (ISO 12882) conveyor belts for aboveground mining and self-extinguishing (ISO 14973) conveyor belts for underground mining, ensuring safety in explosive environments.