Steel Reinforced Conveyor Belt

1.Power plants, mining, and heavy industries can use steel cord–reinforced conveyor belts without any problem.

2.The one-of-a-kind steel cord structure along with the cushioning layer work together to absorb the impact of big materials, thus, not only the equipment gets saved but also no unplanned downtime occurs.

3.Combining the top-notch rubber covers and the highly adhesive steel cords results in a guaranteed, reliable performance over a wide range of operating conditions.

- Hengyi

- Shenyang, Liaoning

- Depends on the actual situation

- 12 million ㎡ /year

- Information

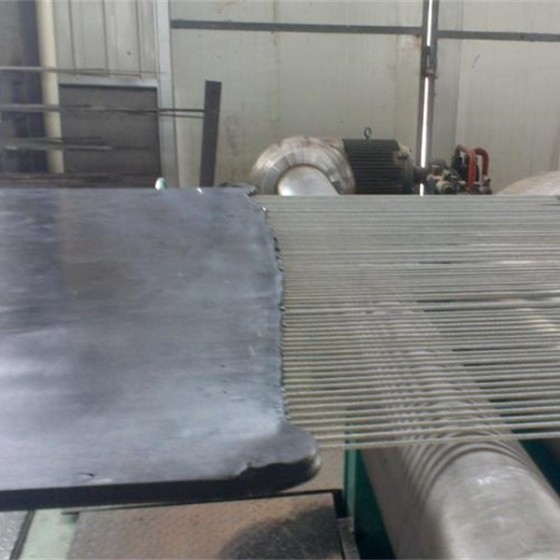

Product Overview:

With high-strength steel cord carcasses, Hengyi steel cord conveyor belts are mainly designed to transport heavy loads and to cover long distances. Hengyi Steel cord and rubber of conveyor belt, when compared with traditional fabric belts, have much higher tensile strength and impact resistance. They can be subjected to continuous conveying of up to 30 km without any problem. Industries like metal mining, coal mining, power generation, ports, and construction widely use these steel cord belts, but they perform most excellently in bucket elevator systems. They are a great alternative to traditional multi-ply fabric conveyor belts.

Suitable Conditions:

Material conveying over long distances (more than 500 m) where normal belts will elongate significantly.

Material conveying over long distances (more than 500 m) where the elongation of normal belts will be quite significant.

Materials that are large, heavy, and of high-impact nature and that can easily destroy traditional belts are examples of such materials.

If the maintenance costs are high and there is a necessity for a stable, long-term, cost-effective solution.

Product Structure & Composition:

Hengyi steel cord reinforced conveyor belt has a multilayer structure:

Top cover: Rubber of high quality with excellent wear, heat, and chemical resistance.

Carcass: Several layers of high-strength fabric (either polyester or nylon) to spread the load evenly and avoid breaking.

Steel cords: The main tensile force and durability are provided by longitudinal steel cords; spacing and diameter can be adjusted.

Bottom cover: Rubber resistant to wear that protects the internal steel cords and ensures smooth operation.

Bonding layer: A mixture of special rubbers makes steel cords, rubber, and fabric stick to each other firmly, which results in higher strength.

Through the use of top-quality calendering and vulcanization machines, partners are able to produce a homogeneous stress distribution thus, they get a stable and dependable long-distance conveying process as a result.

Technical Specifications:

| Item | Range / Description |

| Belt width | 500–2400 mm (customizable) |

| Total thickness | 8–50 mm |

| Top cover thickness | 3–12 mm |

| Bottom cover thickness | 1.5–5 mm |

| Tensile strength | 500–3150 N/mm (customizable) |

| Steel cord diameter | 2.5–12 mm |

| Steel cord spacing | 10–30 mm |

| Fabric type | Polyester (EP) or Nylon (NN) |

| Abrasion resistance | 120–150 mm³ |

Key Features & Advantages:

High tensile strength: Less elongation at heavy-load, long-distance carrying.

Top cover has a good wear resistance and there is a strong bond between the rubber and steel which increases the lifetime of the product.

The cushioning layers effectively help to soak the impact of the material.

A better return on the investment, as well as fewer replacements, will occur.

By the anti-tear design, the advantage is that the risk of a breakdown of the production line is lowered as much as possible.

Installation & Splicing Methods:

Installation Methods:

The installation tools should be ready before starting the work; The belt should be unfurled very carefully; Both ends should be aligned properly and fastened; The belt should be connected.

Splicing options:

Vulcanized joints (recommended), mechanical ...

The steel cord pattern on bucket elevators facilitates stress distribution in a more uniform manner and also running stability getsimproved.

FAQ:

Q:How to find out the required strength rating for a Steel Cord Conveyor Rubber Belting?

A: Take into account the conveying distance, lift height, speed, and capacity. Our specialist technicians will do the calculation and recommend the best solution for you.

Q: What criteria should be used to assess the product quality?

A: Pay attention to the steel cord material, galvanizing quality, rubber to steel adhesion strength, and abrasion resistance. We are able to give you full testing and inspection reports.

Company Strength:

Liaoning Hengyi Rubber Machine Belt Manufacturing Co., Ltd. is a company established in 2018. It is outfitted with modern production and testing equipment such as no-rotor vulcanization testers, abrasion testers, tensile testing machines, aging chambers, and more. With an output of 12 million square meters per year, Hengyi is a supplier of the local as well as the international markets.

The company has been given certification to ISO9000, ISO9001, ISO14001, and OHSAS18001, and it also has the AAA credit enterprise certification. By implementing rigorous quality control measures, the company ensures that each conveyor belt has a stable performance and complies with the international standards. Hengyi runs a worldwide logistics network with proper packaging solutions to guarantee the punctual delivery. Besides, custom specifications are also available to meet the varied customer demands.