- Home

- >

- Products

- >

- Roller Bracket

- >

Roller Bracket

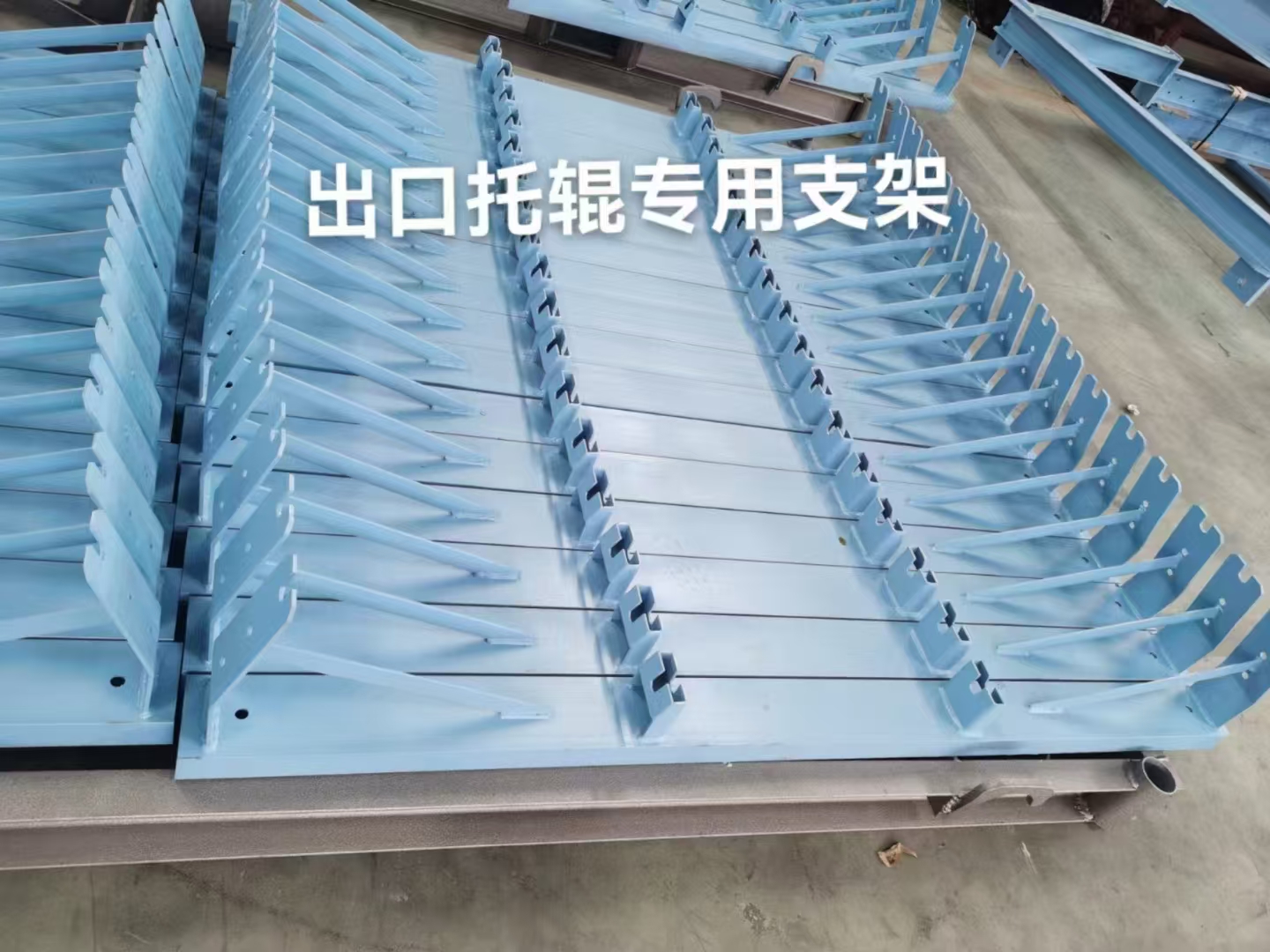

1. Belt conveyor brackets are made of high-strength steel and formed by advanced welding technology. The structure is strong, the load-bearing capacity is strong, and the service life is long.

2. Belt conveyor brackets have undergone surface treatment such as rust removal and painting, and have good anti-corrosion and wear-resistant properties. Belt conveyor brackets can adapt to complex working environments.

3. Belt conveyor brackets adopts a scientific installation hole position and adjustment design, which is easy to install and debug, and can reduce production line downtime.

- Hengyi

- Shenyang, Liaoning

- Depends on the actual situation

- 12 million ㎡ /year

- Information

Are you still troubled by these problems?

● The purchased belt conveyor brackets have poor adaptability, so if you change the conveyor line, you have to re-purchase, and repeated investment increases the cost.

● Belt conveyor brackets have insufficient corrosion resistance and frequently rust and break in humid environments such as coal mines and ports, resulting in production line downtime for maintenance.

● Customized belt conveyor brackets have a long delivery cycle, so they can only wait passively when the project construction period is tight.

The belt conveyor brackets produced by our company rely on the three advantages of universal adaptation, stability and durability, and fast delivery. They have solved the procurement problems of belt conveyor brackets for many companies. Choosing our belt conveyor brackets allows you to reduce maintenance costs and shorten the customization cycle. Next, please take a few minutes to read carefully. I believe our belt brackets will satisfy you.

Introduction of conveyor belt brackets:

Conveyor belt brackets are important components of belt conveyors. Their main role is to support the rollers, fix the position of the rollers, and allow the conveyor belts to run smoothly on a predetermined trajectory. The conveyor belt brackets we produce strictly follow industry standards. Each conveyor belt brackets has undergone precise size control and firmness testing, so that the conveyor belt brackets can maintain stable performance under heavy-duty and high-speed operating conditions. Our conveyor belt brackets series is complete, which can be adapted to conveyor systems with different bandwidth and belt speeds, and provide customers with a full range of support solutions.

Advantages of conveyor belt brackets:

1. High-quality materials and precision manufacturing allow conveyor belt brackets to maintain structural integrity under harsh operating conditions, provide continuous and stable support for the conveyor belt, and reduce the risk of unplanned downtime.

2. After precision calculation of the structural strength and elasticity coefficient, our conveyor belt brackets can maintain the best support state under different load conditions. Whether it is light-load start-up or full-load operation, conveyor roller support frame can effectively absorb shock and vibration, protect the conveyor belt and drive system, and extend the service life of the entire equipment.

3. The diversified conveyor roller support frame series can meet the layout and process requirements of different sites. Whether it is a new construction project or an equipment renovation, a matching conveyor roller support frame solution can be found.

FAQ:

Q: When evaluating the supplier of conveyor roller support frame, what key factors should be paid attention to in addition to price?

A: It is recommended to focus on whether the conveyor roller support frame provided by the supplier adopts standard steel and standardized welding technology, whether the dimensional tolerances of the conveyor roller support frame are strict, whether it can be perfectly matched with the existing system, whether it has a perfect quality management system certification, and whether the supplier can provide timely technical support and after-sales response. We have detailed material certificates and test reports for your review and verification.

Why choose us:

1. We have been deeply engaged in the field of industrial conveying for many years, have accumulated a wealth of product knowledge and manufacturing experience, and understand the differentiated needs of various industries for conveying equipment.

2. We implement the whole process of quality inspection from the storage of raw materials to the delivery of finished products. Each conveyor roller support frame meets the design standards and customer requirements.

3. We provide professional technical consultation, perfect after-sales support, and can provide customized product solutions according to customer needs.

4. We have a mature production system and supply chain management capabilities, which can enable timely delivery of orders and provide reliable guarantees for customers' production plans.

5. Our products have passed a number of international authoritative certifications, and the quality of our products meets international standards.