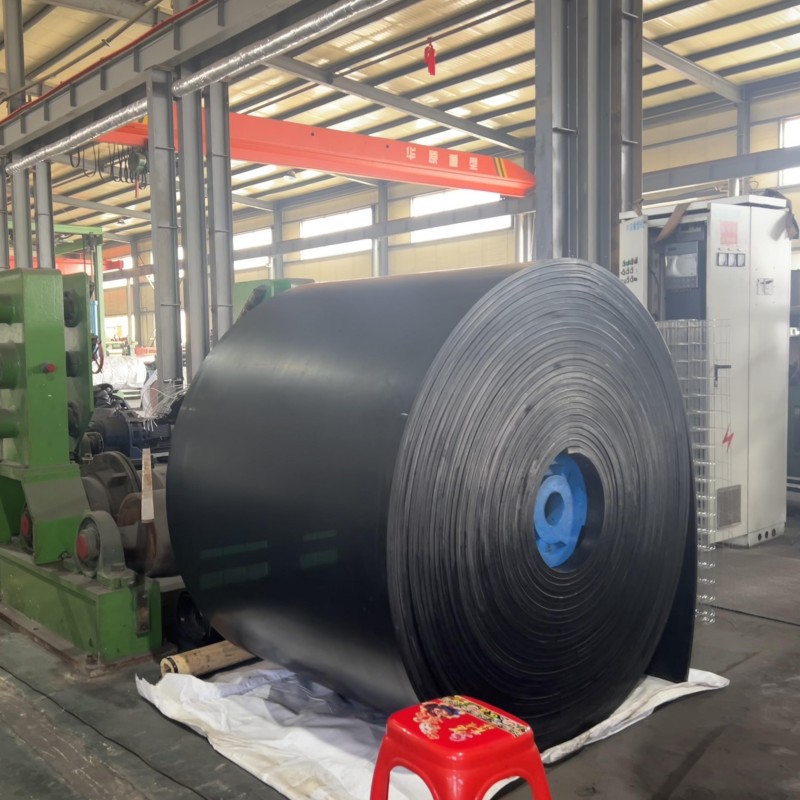

Nylon Conveyor Belt for Cement Plant

1. Our company provides nylon conveyor belts of various specifications to meet different strength requirements, and is particularly good at producing high-strength conveyor belts.

2. Nylon conveyor belts use high-strength corrugated canvas, which can effectively absorb impact, reduce the risk of tearing, and maintain high joint efficiency.

3. We provide nylon conveyor belts of various sizes to meet different working conditions.

- Hengyi

- Shenyang, Liaoning

- Depends on the actual situation

- 12 million ㎡ /year

- Information

Core advantages of nylon fabric conveyor belt:

1. Strength and durability of nylon fabric conveyor belt:

The nylon fabric conveyor belt uses NN canvas layer woven with imported high modulus nylon fiber, with a tensile strength of up to 300-600N/mm.

The unique warp and weft weaving process allows uniform force in all directions to avoid local stress concentration.

The steel wire core reinforcement structure (ST model) is optional, which is suitable for ultra-long distance and large-volume transportation scenarios.

According to actual application cases, under the same working conditions, the service life of our nylon fabric conveyor belt is 3-5 times longer than that of ordinary products.

2. Impact resistance of industrial nylon belt:

The patented corrugated canvas layer structure can effectively absorb and disperse the impact energy of materials.

The specially designed edge reinforcement treatment process significantly reduces the risk of deviation and longitudinal tearing.

The dynamic troughing property of industrial nylon belt is good, ensuring the stability of material transportation.

Application of Nylon Conveyor Belt for Cement Plant:

Industrial nylon belt plays a key role in cement plant production, and is particularly suitable for high temperature and high wear environment. In the raw material conveying link, the high-strength nylon structure of industrial nylon belt can withstand long-term friction with sharp materials such as limestone; when conveying clinker, industrial nylon belt can withstand high temperature above 120℃ to prevent clinker adhesion and burning damage; and in the cement finished product packaging section, the anti-static design of the conveyor belt ensures safe and dust-free powder conveying. Compared with ordinary conveyor belts, the service life of our industrial nylon belt can be increased by 3-5 times, greatly reducing the equipment maintenance cost and downtime of cement plants.

Maintenance methods of nylon conveyor belt:

First, a regular inspection system should be established to check the surface wear, edge damage and joint condition of the nylon conveyor belt every week, focusing on monitoring the thickness of the cover rubber (using a laser thickness gauge) and the delamination of the canvas layer;

Second, maintain scientific cleaning, use special rubber cleaners to remove the adhered materials on the surface of the nylon conveyor belt (especially high-temperature residues such as cement clinker), and avoid using strong acid and alkali cleaning agents;

Third, dynamically adjust the tension to ensure that the operating tension of the nylon conveyor belt is maintained within the range of ±10% of the standard value. Too tight will accelerate joint fatigue, and too loose will easily cause slipping;

Fourth, use professional anti-deviation devices and buffer rollers, and install wear-resistant linings at the blanking port to reduce impact wear;

Finally, establish a belt body file, record the cumulative running time, maintenance times and wear rate of the nylon conveyor belt, and perform preventive replacement in combination with the life prediction model provided by the manufacturer. It is recommended that professionals conduct comprehensive inspections every quarter and retain 2-3 meters of spare belt bodies for quick repair.

Core advantages of the enterprise: strict quality control, technological protection.

We use precision testing equipment and standardized processes to build the quality defense line of industrial nylon belt:

Full process testing - from raw materials entering the factory to finished products leaving the factory, 100% performance index testing is carried out, and nylon fabric conveyor belts all meet ISO and other international standards;

Intelligent testing system - using advanced equipment such as laser thickness gauges and tensile testing machines, the key parameter detection accuracy of industrial nylon belts reaches ±0.5%;

Zero defect commitment - each batch of nylon fabric conveyor belts supports customers to inspect the factory and goods, and quality problems can be traced for life.

Use digital quality control to give conveyor belts a longer life, so that customers can save worry and cost.