- Home

- >

- Products

- >

- Chevron Belt

- >

Chevron Belt

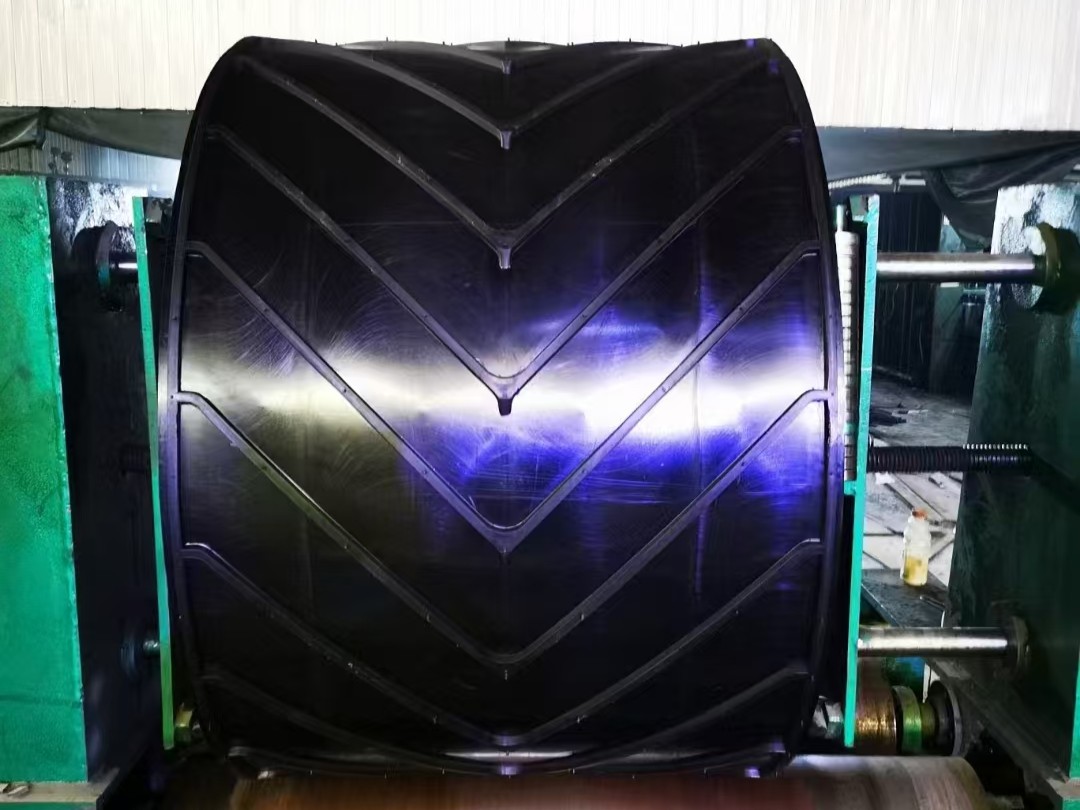

1. Rubber conveyor belt adopts a unique pattern design that can increase the friction between the belt surface and the material, effectively preventing the material from slipping and slipping in inclined transportation.

2. Compared with smooth conveyor belts, rubber conveyor belt can be competent for conveying tasks with greater inclination angles, helping you optimize equipment layout and save space.

3. Rubber conveyor belt is made of high-strength skeleton material and wear-resistant rubber formula, and the belt body has strong tear resistance and long service life under complex working conditions.

- Hengyi

- Shenyang, Liaoning

- Depends on the actual situation

- 12 million ㎡ /year

- Information

The material slips and the conveying efficiency is low? Rubber conveyor belt provides you with a stable and efficient anti-skid solution!

Dear purchasing managers, equipment engineers and project decision makers, when evaluating bulk material conveying systems, have you ever affected production efficiency and cost control due to the following issues?

● Because the conveyor belt skids, the material returns and the conveying efficiency does not meet expectations?

● In the inclined section, because of insufficient friction, the inclination angle had to be reduced, sacrificing valuable site space?

● In the face of loose or special materials, ordinary smooth conveyor belts cannot provide sufficient grip, resulting in unstable conveying?

These problems are exactly the original design intention of rubber conveyor belt! The rubber conveyor belt we manufacture not only increases the raised pattern on the surface, but also systematically improves the friction, adaptability and reliability of the conveying system through scientific design and professional manufacturing. Our rubber conveyor belt has helped many industry customers solve anti-skid problems, and achieved a more compact equipment layout and a more stable material flow. Please take a few minutes to continue reading to learn about our professional rubber conveyor belt.

Introduction of rubber conveyor belt:

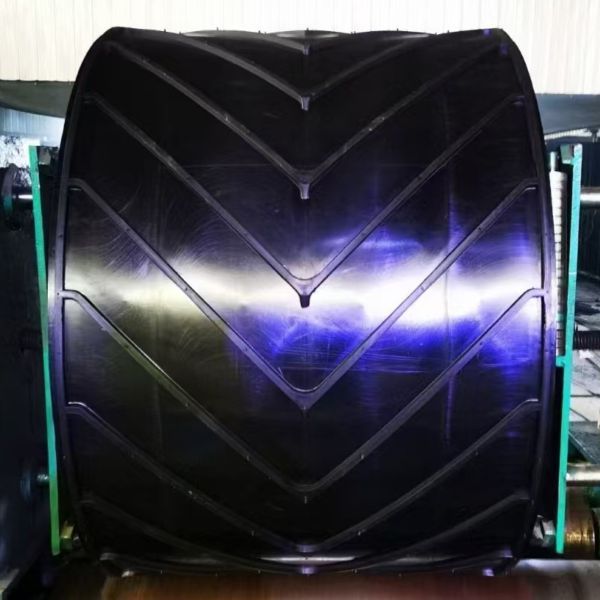

Chevron conveyor belt is an industrial conveyor belt with a raised pattern cast on the belt body covering glue. These patterns are not simple decorations. The core function is to increase the coefficient of friction on the surface of the chevron conveyor belt, thereby ensuring the stability of the material during horizontal or inclined transportation. The chevron conveyor belt is particularly suitable for working conditions with gradients or where material slippage needs to be prevented.

Advantages of chevron conveyor belt:

1. By providing reliable friction, the chevron conveyor belt allows materials to be transported smoothly according to a preset path, reducing the risk of production interruption and ensuring the continuity of overall operations.

2. Chevron conveyor belt expands the range of applicable angles of the equipment, allowing you to have greater flexibility in the planning and design of the production line without having to compromise due to terrain restrictions.

3. The chevron conveyor belt has excellent wear and tear resistance, which means a longer replacement cycle. At the same time, the stable operation of the chevron conveyor belt reduces the additional equipment wear and maintenance requirements caused by slippage, which can save comprehensive costs.

FAQ:

Q: How do I choose the most suitable pattern type for my material?

A: The choice of chevron rubber conveyor belt mainly depends on the particle size, humidity and conveying inclination of the material. For example, herringbone is suitable for most bulk materials and has good orientation, while fishbone pattern is more suitable for packaging boxes. Please provide your material information, and our engineers will recommend the best choice for chevron rubber conveyor belt for you.

Q: After the pattern of the chevron rubber conveyor belt is worn out, will it affect the anti-skid effect?

A: It will. The pattern height of the chevron rubber conveyor belt is the key to ensuring anti-skid ability. We use a covering rubber formula with excellent wear resistance, and the base of the pattern and the belt body are firmly combined to delay the wear of the pattern to the maximum extent and extend the effective service life of the chevron rubber conveyor belt.

Q: Have your products been certified by authorities?

A: Of course, we can provide a picture of the certificate.

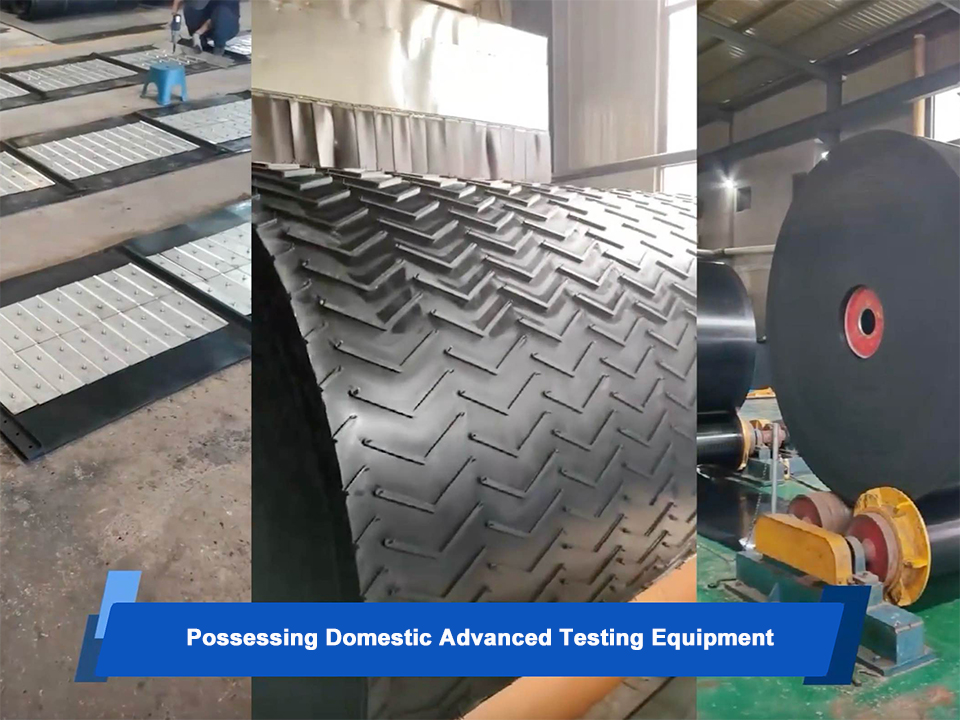

Our factory:

Our factory has always used strict standards to control product quality. We continue to invest in the introduction of advanced domestic testing equipment, and establish a full-process testing system from the acceptance of raw materials to the delivery of finished products. Each batch of chevron rubber conveyor belt will pass precision equipment verification, so that the performance meets international and industry requirements. All test data are recorded and archived in electronic form to form a complete database, which can not only support the full cycle of product traceability, but also provide a basis for optimizing production and testing processes. In the future, we will continue to increase resource investment, upgrade equipment and technology, and use industry-leading quality standards to provide customers with higher-quality chevron rubber conveyor belt.