Why Are Anti-Slip Conveyor Belts Essential for Chemical and Bulk Material Production Lines?

2026-01-21 16:21In modern chemical plants, mining operations, ports, and building materials industries, bulk material conveying is a critical part of keeping production running smoothly. These materials are often free-flowing, easy to slide, dusty, corrosive, or highly abrasive. Once rollback, spillage, or buildup occurs on inclined sections, curves, or speed-change zones, it can trigger a chain of problems—lower efficiency, serious material loss, higher safety risks, environmental pollution, and even equipment damage and unplanned downtime.

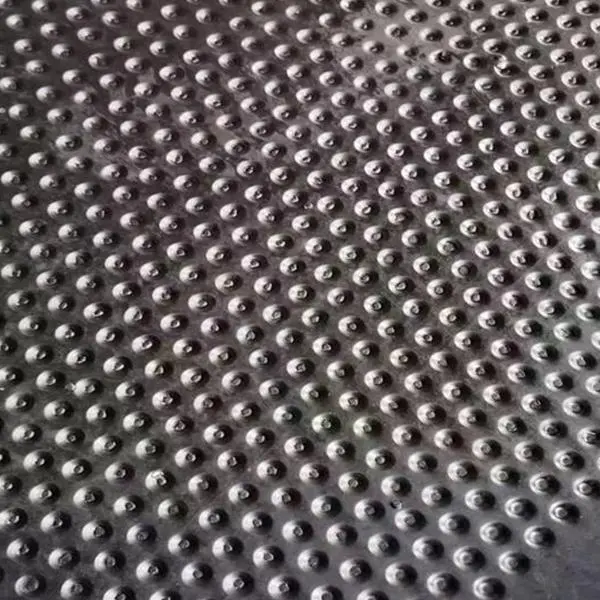

An Anti slip conveyor belt is a key solution to these challenges. It’s not just "adding a pattern to the surface"—it directly determines whether a production line can operate efficiently, safely, and continuously. Below, we break down the real problems, core advantages, and performance comparisons to explain why chemical and bulk material lines simply can’t do without anti-slip belts.

How Anti-Slip Belts Solve Core Bulk Conveying Problems.

Common Challenges in Bulk Material Handling.

· Material rollback and spillage:

On standard flat belts, once the incline exceeds 18°–22°, materials tend to roll back or spill sideways, sharply reducing throughput and causing floor buildup.

· Safety risks:

Spilled chemical materials (acids, alkalis, combustible dust) can lead to corrosion, explosions, or toxic exposure. In mining, flying aggregates can injure workers.

· Environmental pollution and waste:

Dust and scattered material increase emissions and waste. Losses can reach hundreds of dollars per ton.

· Equipment wear and downtime:

Rolled-back material can jam pulleys and idlers, causing belt mistracking, tearing, and bearing failure—leading to frequent maintenance.

· Space and efficiency limits:

Flat belts require small incline angles, taking up more floor space and limiting compact plant layouts.

Anti-slip belts use raised surface patterns to improve grip and material retention, effectively addressing these issues.

Key Advantages of Anti-Slip Conveyor Belts:

| Performance Indicator | Standard Conveyor Belt | Round-Pit Anti-Slip Conveyor Belt |

| Maximum safe incline | ~18°–22° | 25°–45° |

| Material rollback rate | High (≈20% at 30°) | Very low (<5%, often near zero) |

| Spillage/dust risk | High | Low |

| Residue & cleaning difficulty | High | Low (round pits reduce adhesion, easy to clean) |

| Wear & chemical resistance | Average | Excellent (premium rubber + reinforced carcass) |

| Material types | Dry, regular lumps | Powder, granules, lumps, sticky, wet materials |

| Operational stability | Moderate | High |

Why Chemical Production Lines Rely Heavily on Anti-Slip Belts?

Chemical materials are often corrosive and may pose dust explosion risks. A round-pit surface structure not only prevents sliding but also reduces residue and splashing:

· Leak prevention and corrosion control:

The pit pattern firmly holds particles, minimizing spills that could corrode equipment or floors.

· Dust control and safety:

Reduced dust dispersion lowers explosion risks and helps meet hazardous material and dust control standards.

· Chemical-resistant compounds:

High-quality natural rubber formulations resist acids and alkalis, ensuring long-term stability without cracking or degradation.

In these environments, an Anti slip conveyor belt plays a direct role in both safety compliance and operational reliability.

Why Mining, Ports, and Building Materials Depend on Anti-Slip Designs?

· Steep incline conveying:

From crushers to stockpiles, or from ship holds to docks, incline angles often exceed 30°. Round-pit patterns keep material moving upward steadily.

· Higher throughput:

Stable conveying can increase line capacity by 20%–40%.

· Easy cleaning and low maintenance:

Sticky or wet materials are less likely to cling to the belt surface, reducing cleaning time and maintenance frequency.

For these heavy-duty industries, an Anti slip conveyor belt is not an upgrade—it’s a necessity.

Choosing the Right Anti-Slip Belt Means Choosing Productivity.

When sourcing conveyor belts, buyers should focus on belt material, surface pattern, carcass strength, and proven real-world applications.

If your production line is facing material rollback, excessive dust, frequent cleaning, or space limitations, feel free to contact Liaoning Hengyi Rubber Machine Belt Manufacturing Co., Ltd. for sample testing or custom solutions. Our experienced team can recommend the most effective anti-slip configuration based on your material type, incline angle, and capacity requirements—helping you build a safer, more efficient conveying system.