Installation and Usage Advantages of Steel Cord Conveyor Belts

2026-02-06 10:19In modern industrial production and logistics, conveyor belts are a key part of operations. Among various types, steel cord conveyor belts stand out for their excellent load capacity, durability, and stable performance. They are the preferred choice for mining, steel, ports, and other heavy-duty industries. Let’s take a closer look at the advantages of steel cord conveyor belts in both installation and daily use, and why choosing a high-quality belt matters.

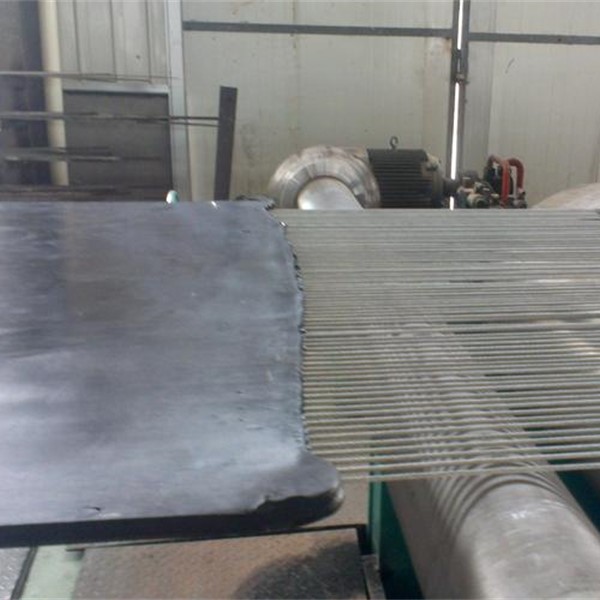

Unique Structure of Steel Cord Conveyor Belts:

The main difference between a steel cord conveyor belt and a standard fabric belt lies in the core structure — the steel cord core.

Normal conveyor belts usually have a fabric or fiber-reinforced core. These are fine for medium loads and short distances, but can stretch, tear, or wear out quickly under long-distance or heavy-duty conditions.

A steel cord conveyor belt embeds high-strength steel cords in multiple layers of rubber, creating a strong, impact-resistant structure. This design not only increases load capacity but also ensures stable operation under long-term, high-load conditions.

We also offer customization for our steel cord conveyor belts. Width, thickness, layers, and steel cord type can be adjusted according to your working conditions, making installation and operation more flexible and reliable.

Installation Advantages:

Installing a steel cord conveyor belt is straightforward. With proper tension adjustment and professional splicing, the belt can run steadily for years, reducing early wear and potential failures.

The standardized interface design also makes maintenance and replacement easier. If a section needs repair during operation, it can be quickly removed and reinstalled, minimizing downtime. For high-intensity, continuous production lines, this helps improve efficiency and maintain safety.

Usage Advantages:

Steel cord conveyor belts are wear-resistant and long-lasting. The rubber-encased steel cords improve overall durability while enhancing corrosion and heat resistance. In heavy industries like coal, mining, and steel, where sharp or hot materials are transported continuously, these belts maintain stable performance.

They also have an optimal friction coefficient and uniform tension. For long-distance, high-tonnage transport, they require less driving power, helping save energy.

Here’s a quick comparison of steel cord conveyor belts versus standard fabric belts:

| Feature | Steel Cord Conveyor Belt | Standard Fabric Belt | Why It Matters |

| Maximum Load Capacity | High | Medium | Steel cords provide extra strength and impact resistance |

| Wear Resistance | High | Medium-Low | Rubber-encased steel cords improve durability |

| Lifespan | Long | Medium | Suitable for long-distance, heavy-duty, continuous operation |

| Heat & Corrosion Resistance | Good | Average | Stable performance in high-temperature and corrosive environments |

| Power Requirement | Low | High | Lower friction saves energy |

| Maintenance Convenience | High | Medium | Standardized design makes repairs and section replacements easy |

If you’re looking for a conveyor belt capable of handling heavy-duty transport, our steel cord conveyor belts can be customized to your needs, providing stable, efficient, and long-lasting solutions for your production line.