How does the Industrial Conveyor Belt System Affect the New Industry?

2025-05-23 16:50In the industrial scene in the modern environment, more and more attention is paid to efficient and cost-effective material handling methods, and the demand is growing year by year.

In the industrial scene, the industrial conveyor belt system has also become the mainstay equipment for many enterprises' operations, because it can realize the seamless transportation of goods, improve the production efficiency of enterprises and improve the overall workflow efficiency.

The industrial conveyor belt system is designed to transport materials or products from one point to another in a continuous cycle, thereby promoting automation. Compared with the manual labor of the old era, this method minimizes the repetitive labor of manual labor. This industrial conveyor belt system has a wide range of uses, mostly used in mining, automobiles, ports and other industries.

The main advantages of the industrial conveyor belt system:

1. Improve productivity:

One of the main advantages of the industrial conveyor belt system is the ability to handle large amounts of materials with minimal human intervention. It can be seen that this method improves the productivity of the enterprise. Compared with manual labor, the material moves faster and more efficiently, improves accuracy, reduces error rates, and increases the overall output of the enterprise.

2. Customization for special applications:

Based on the overall needs of different industries, we can customize our products. Some scenarios require high-temperature conveyor belts, while others are suitable for stronger wire rope conveyor belts. We will recommend the right product type for you based on your industry.

3. Reduce the risk of injury:

After using industrial conveyor belt systems, companies can avoid potential risks of manual handling by employees, such as lifting injuries, repetitive strain injuries, or workplace accidents. By reducing the physical requirements on workers, industrial conveyor belt systems help create a safer working environment.

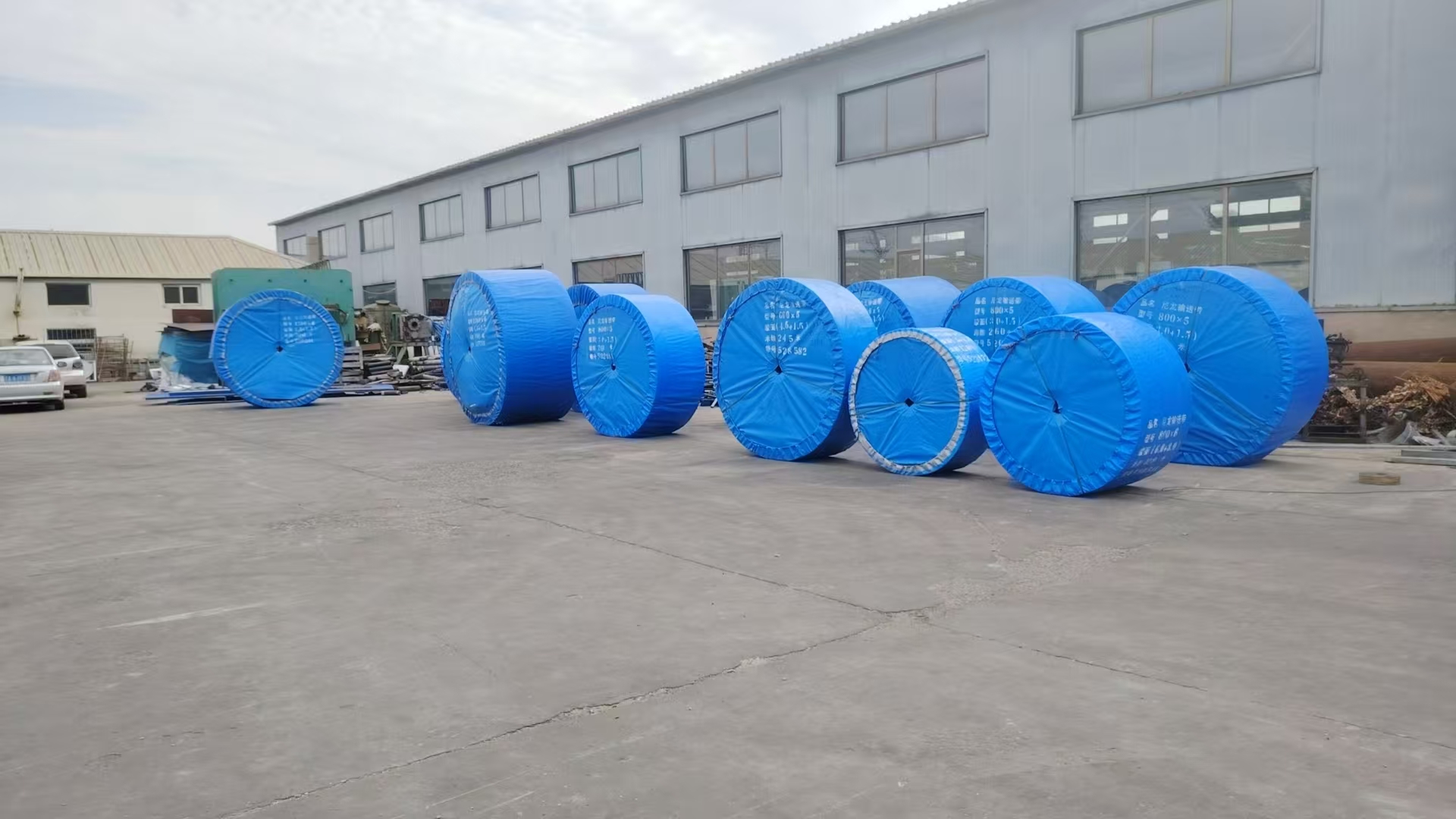

Our strength base:

In 2021, it passed the IS09000 standard certification, IS09001 quality management system certification, IS014001 environmental management system and OHSAS18001 occupational safety and health management system standard certification, and obtained the AAA credit enterprise certification. The company has complete testing methods and has domestically excellent testing equipment, including a rotorless vulcanizer, Mooney viscometer, roller abrasion testing machine, 10-ton tensile testing machine, 2-ton tensile testing machine, aging box, high resistance meter, and roller friction Testing machines, etc.The company has advanced production equipment, including GK -270 internal mixer, 110 internal mixer, 1730 four-roller calendering unit, 1530 four-roller Calendering unit, 1.6-meter wide forming machine, 2-meter wide forming machine, and 10-meter steel wire core and fabric core conveyor belt vulcanization production line produced by Qingdao Beihai Machinery Equipment Company, 10-meter steel wire rope flat plate vulcanization production line produced by Liaoning Tieling, 8-meter double-layer Flat plate vulcanization production line, 10-meter single-layer flat plate vulcanization production line, molding six-layer laminating machine production line, molding four-layer laminating machine production line, with an annual output of 12 million square meters. The products are distributed in major provinces and cities across the country.