Cleaning of Steep Angle Sidewall Conveyor Belts

2025-10-30 14:05Cleaning

Keeping your conveyor clean ensures smooth operation and extends its lifespan. You will find that cleaning requirements differ between steep angle sidewall conveyor belts and standard conveyor systems.

Steep angle sidewall belts use corrugated sidewalls and cleats. These features restrict your cleaning options compared to standard systems.

Standard conveyor systems allow you to use a wider range of cleaning tools and techniques. Their open design makes cleaning easier.

Cleaning steep incline conveyors often requires specialized equipment, such as a belt thumper. You do not usually need this for standard conveyors.

You may find that debris and material buildup collect in the pockets formed by the sidewalls and cleats. This buildup can cause blockages or reduce efficiency. You should use targeted cleaning methods, like high-pressure air or water jets, to reach these areas. For standard conveyors, you can often use brushes, scrapers, or automated belt cleaners.

Note: Choose cleaning tools that match your conveyor’s design. Using the wrong method can damage the belt or reduce its lifespan.

A clean conveyor runs more efficiently and reduces the risk of unexpected breakdowns. You save time and money by preventing buildup and keeping your system in top condition.

Cost Factors

Initial Cost

You need to consider the initial investment when choosing between a steep angle sidewall conveyor belt and a standard conveyor system. Steep angle sidewall conveyor belts often come with a higher upfront price due to their specialized design, reinforced materials, and added components like cleats and sidewalls. These features allow you to move materials at sharp inclines, but they also increase the manufacturing complexity and cost.

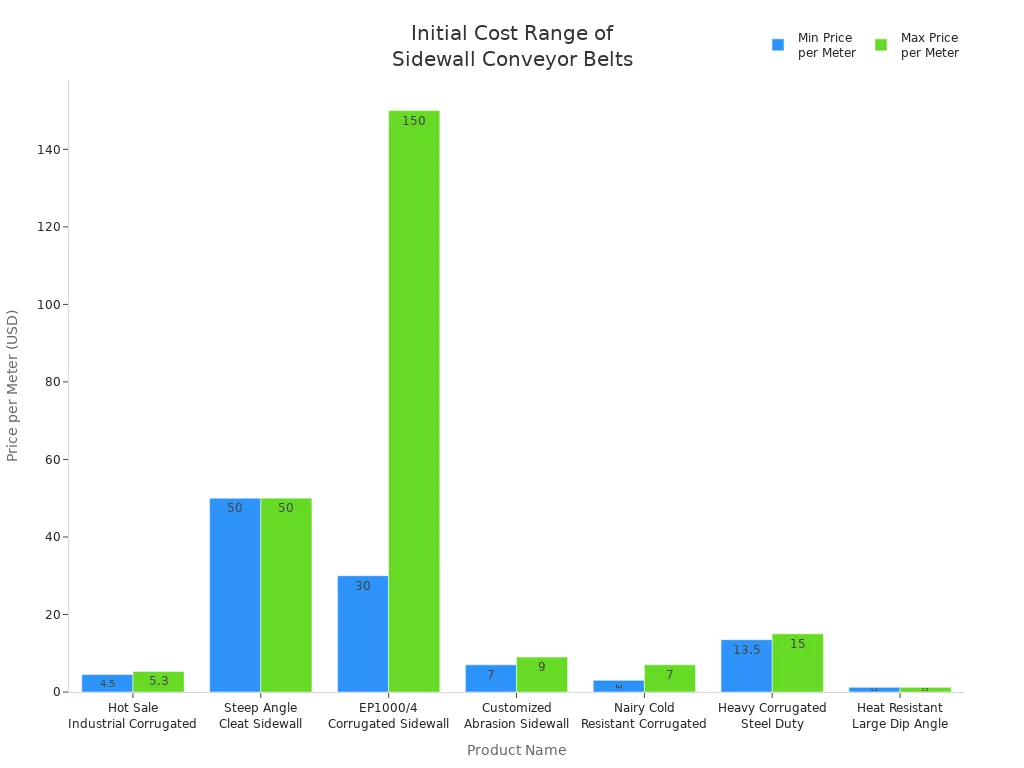

You can see the range of prices for steep angle sidewall conveyor belts in the table below:

Standard conveyor systems usually cost less per meter because they use simpler belts and fewer specialized parts. You may find that the price for a basic flat belt system is much lower, especially if you do not require advanced features. However, if your facility has space constraints or needs to move materials at steep angles, the higher initial cost of a sidewall system can be justified by the space savings and increased efficiency.

Note: You should always factor in your facility’s layout and long-term needs. Sometimes, a higher upfront investment leads to greater savings over time.

Operating Cost

You must also look at the ongoing expenses of running your conveyor system. Steep angle sidewall conveyor belts can help you save on operating costs in several ways. Their ability to move materials vertically reduces the need for multiple transfer points, which means less energy loss and fewer maintenance stops. You also benefit from lower spillage rates, so you waste less material and spend less time cleaning up.

Here are some key factors that affect operating costs:

Energy Efficiency: Steep angle systems often use less energy per ton moved because they shorten the conveyor path and reduce friction.

Maintenance: You may spend less on repairs and replacements due to the robust construction of sidewall belts. However, specialized parts like cleats and sidewalls can cost more to replace.

Downtime: Fewer transfer points and less spillage mean you experience fewer stoppages, which keeps your operation running smoothly.

Cleaning: The design of steep angle sidewall belts helps keep materials contained, so you spend less time and money on cleaning compared to standard systems.

Standard conveyor systems may have lower maintenance costs for basic parts, but they often require longer runs and more frequent cleaning, especially if you handle loose or fine materials. Over time, these extra tasks can add up and offset the lower initial investment.

Tip: When you evaluate total cost of ownership, include both the initial purchase price and the ongoing operating expenses. This approach helps you choose the most cost-effective solution for your facility.

Applications

Where Steep Angle Sidewall Conveyor Belt Excels

You find the Steep Angle Sidewall Conveyor Belt in industries that demand efficient material movement in tight spaces or at sharp inclines. This system stands out when you need to move bulk materials vertically or near-vertically, especially where floor space is limited or spillage control is critical.

You see these belts in action where traditional conveyors cannot perform. For example, in mining, you can move minerals from deep underground to the surface without long horizontal runs. In construction, you lift heavy materials vertically on crowded sites, saving valuable ground area. In agriculture, you transport crops from storage units to tall silos with ease. Waste recycling plants use these systems to handle large volumes in confined spaces, boosting capacity and efficiency.

The unique structure of sidewall conveyor belts keeps materials contained, even on steep inclines. Corrugated sidewalls and cleats create secure pockets, so you experience less spillage and cleaner operations.

Standard Conveyor Uses

You rely on standard conveyor systems for straightforward, horizontal, or gently inclined transport. These systems work best in facilities with ample floor space and minimal elevation changes. You often see them in warehouses, distribution centers, and manufacturing plants where you need to move boxes, packages, or bulk goods over long distances.

Standard conveyors handle a wide range of materials, but they struggle with steep inclines or limited space. You may need longer conveyor runs or additional transfer points to achieve the same elevation change as a steep angle system. This setup can increase your footprint and the risk of material loss.

Use standard conveyors for:

Moving packaged goods in logistics centers

Transporting materials between workstations in factories

Handling bulk products on gentle slopes in processing plants

When you face challenges with space, incline, or spillage, you gain more value by choosing a Steep Angle Sidewall Conveyor Belt. In other cases, standard conveyors provide a reliable and cost-effective solution for everyday material handling.

Pros & Cons

Steep Angle Sidewall Conveyor Belt

You gain several operational advantages when you select a Steep Angle Sidewall Conveyor Belt for your facility. This system delivers smooth operation and reliable performance, even in challenging environments. You benefit from a flexible layout, low noise levels, and the ability to transport materials at large inclined angles. Maintenance becomes easier because the system uses fewer equipment parts. You can handle a wide range of material densities, making this conveyor highly adaptable across industries.

Tip: You can achieve efficient material elevation in confined spaces and reduce the need for multiple transfer points.