10 Common Questions You Must Know Before Buying a Anti Slip Conveyor Belt

2026-01-31 11:59In real-world operations, many companies only start looking into round dimple conveyor belts after facing constant belt slipping, difficult cleaning, or rising replacement costs.

But the real question is: Is this type of belt actually right for your application?

Before making a purchasing decision, understanding the following 10 common questions can save you time, money, and a lot of operational trouble.

When should you consider a round dimple conveyor belt?

If your conveyor system operates at a steep incline, or the materials tend to roll or slide easily, a standard flat belt often struggles to maintain stable conveying.

Once issues like material rollback, pile-up, or reduced efficiency appear, a round dimple Anti slip conveyor belt is usually a practical solution.

For these conditions, we offer multiple specifications designed to match different incline angles and material characteristics, helping improve stability in inclined conveying.

What’s the difference between round dimples and regular anti-slip patterns?

Traditional anti-slip patterns mainly rely on surface friction.

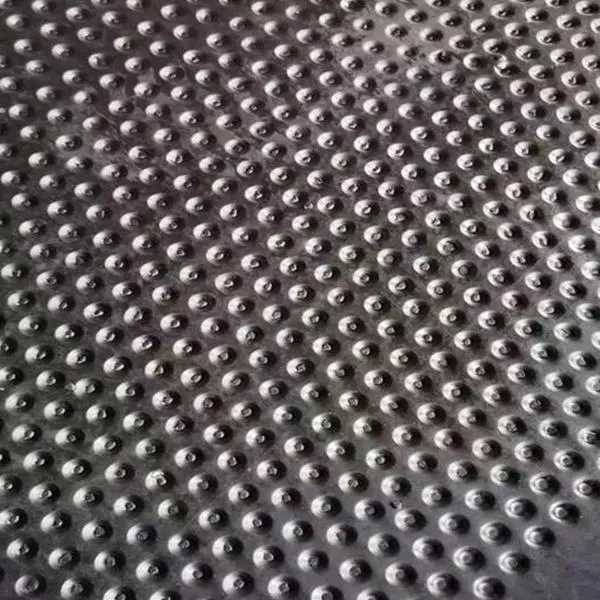

Round dimple patterns, on the other hand, use evenly distributed recessed pits to create a physical barrier on the belt surface.

This structure doesn’t just increase friction—it also limits rolling movement, keeps materials centered on the belt, and results in more stable operation overall.

What incline angle can a round dimple anti-slip belt handle?

In most real applications, round dimple conveyor belts perform reliably at incline angles up to 45°.

That said, steeper is not always better. The optimal angle depends on material shape, load weight, and belt speed.

Based on actual project experience, we recommend suitable dimple sizes and belt constructions rather than simply pushing for the maximum incline.

What types of materials work best with round dimple conveyor belts?

Typical suitable materials include granular materials such as coal or crushed stone, materials that roll or slide easily, and soft bags or regularly shaped packages.

For very fine powders or highly sticky materials, a more detailed evaluation of the operating conditions is usually required.

Is maintenance more expensive compared to flat belts?

At first glance, a round dimple Anti slip conveyor belt may cost more than a standard flat belt.

However, in real operation, reduced slipping and longer service life usually mean fewer shutdowns and fewer replacements.

From a total cost of ownership perspective, maintenance costs are often easier to control over the long term.

We also provide wear-resistant belt options to help reduce downtime and replacement frequency.

Does the dimple structure make cleaning harder?

This is a common concern, especially in logistics operations.

In practice, round dimple belts have continuous surfaces with no dead corners. When combined with drainage holes or hollow dimple designs, water drains quickly after washing, allowing faster drying and less residue buildup.

For logistics environments, we offer smooth-surface, easy-to-clean versions that meet daily cleaning and hygiene requirements.

Are round dimple belts more prone to wear?

Under long-term heavy load or high-friction conditions, flat belts are more likely to suffer surface wear or localized damage.

Round dimple conveyor belts distribute force more evenly, and when made with wear-resistant compounds, they typically offer better durability and longer service life.

How do selection priorities differ by industry?

· In logistics sorting, the focus is on anti-slip performance and package stability.

· In mining applications, wear resistance, impact resistance, and belt lifespan are critical.

· Manufacturing environments often prioritize surface protection for parts and components.

Our round dimple Anti slip conveyor belt solutions have been used across logistics, mining, and manufacturing, with configurations tailored to each operating condition.

How can you tell if a round dimple belt fits your application?

Before selecting a belt, it helps to confirm several key factors: incline angle, material behavior (especially rolling tendency), cleaning and hygiene requirements, and operating load and duty cycle.

If multiple factors align with these conditions, a round dimple belt is usually a sound choice.

What are common mistakes when purchasing round dimple conveyor belts?

Many buyers assume anti-slip belts are always far more expensive than flat belts, blindly pursue maximum incline angles, or focus too much on pattern complexity while ignoring actual operating conditions.

In reality, practical selection matters more than specifications alone.

Simple comparison: Round dimple belt vs. flat belt.

| Item | Round Dimple Conveyor Belt | Flat Belt |

| Suitable incline | Medium to steep | Low incline |

| Anti-slip performance | High | Limited |

| Handling rolling materials | Stable conveying | Prone to slipping |

| Cleaning & drying | Easier | Average |

| Service life | Longer | Shorter |

A round dimple conveyor belt is not an “upgraded” version of a flat belt—it’s a solution designed for specific operating challenges.

If you’re dealing with belt slipping on inclines, cleaning difficulties, or frequent belt replacements, understanding different anti-slip belt structures can help your conveyor system run more smoothly, reliably, and predictably.