Steel Cord Belt Rubber Belt

1. Rubber belt uses a special heat-resistant rubber cover layer and glue, which can adapt to complex working environments.

2. After the rubber belt is installed and tensioned, there is almost no need to adjust it. The trajectory is stable and it is not easy to deviate.

3. Rubber belt has high structural stability, long service life and low maintenance costs.

- Hengyi

- Shenyang, Liaoning

- Depends on the actual situation

- 12 million ㎡ /year

- Information

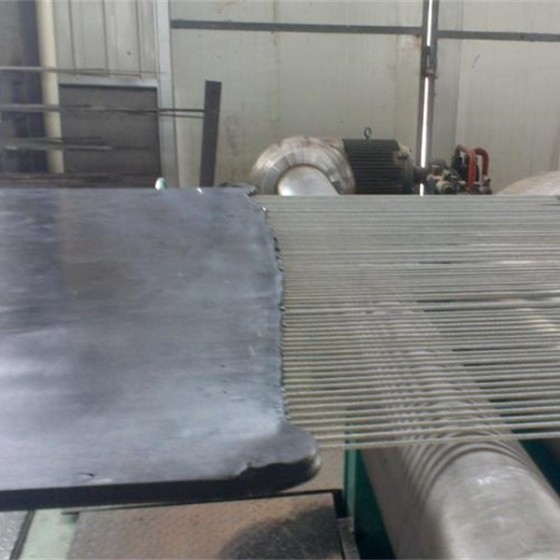

Introduction of rubber belt:

Rubber belt is a conveyor belt with a core tensile body of multiple wire ropes arranged vertically at a predetermined spacing. Rubber belt is composed of core rubber, wire rope, cover layer and side rubber. Rubber belt is widely used in coal, mining, metallurgy, electric power, chemical industry and other fields to transport materials.

Characteristics of rubber belt:

1. High tensile strength: the tensile strength of a single wire rope can reach thousands of newtons, and the tensile strength of rubber belt is dozens of times that of ordinary fabric belt.

2. Strong impact resistance: rubber belt can withstand strong working tension and provide strong impact resistance, especially suitable for conveying large and sharp materials.

3. Long conveying distance: industrial conveyor belt can avoid the equipment costs caused by multi-stage transportation.

4. Excellent groove formation and lateral rigidity: under the support of the roller group, the industrial conveyor belt can form a deep and stable groove shape, which can increase the loading capacity and prevent material from spilling. The good lateral rigidity of the industrial conveyor belt can also resist the partial load pressure of the material and reduce the risk of deviation.

5. High fatigue resistance: industrial conveyor belt has excellent dynamic bending fatigue resistance, and it is not easy to break when passing through the drum repeatedly.

6. Long service life: under reasonable use and maintenance, the service life of industrial conveyor belt is usually much longer than that of fabric core conveyor belt.

Application scenarios of industrial conveyor belt:

1. Mining and processing: wear-resistant conveyor belt can be used to transport crushed gravel and gravel such as granite and limestone.

2. Port terminal: the wear-resistant conveyor belt can be connected to the ship unloader to handle a large amount of bulk cargo during the unloading link.

3. Iron and steel metallurgical industry: wear-resistant conveyor belt can transport high-temperature materials such as iron ore and sintered ore over long distances.

Why choose us:

1. Strong production capacity: we have a number of production lines and introduce high-end advanced equipment, and we also have a professional production team with strong strength.

2. Strict quality control: we fully implement the requirements of the quality management system, and every wear-resistant conveyor belt has undergone strict testing.

3. The products are rich and diverse: our company has wear-resistant conveyor belt, patterned conveyor belt, large-inclination wavy flange conveyor belt, high-temperature resistant conveyor belt and other products, the product specifications are sufficient to meet your needs.

4.Perfect after-sales service: you can consult for free before the sale, and we have professionals to assist in understanding your needs. We are efficient and responsible for after-sales, and telephone, e-mail, and remote services are permanently free!