One-Stop Solution for Industrial Conveyor Belts and Supporting Equipment

2025-08-12 14:09In the Market

The rapid development of heavy industry worldwide has made material transportation a major challenge, and the demand for Nylon industrial conveyor belts has continued to rise.

The demand for industrial conveyor belts is particularly high in industries such as mining, metallurgy, power generation, building materials, and chemicals. The corrosion- and wear-resistant properties of nylon industrial conveyor belts effectively improve efficiency and safety in production environments.

In today's society, customers are not only concerned with product performance but also prioritize environmental friendliness, intelligent operation, and ease of maintenance. Nylon industrial conveyor belts also offer excellent overall performance, providing essential support for various industries.

Structural and Technological Innovations in Industrial Conveyor Belts

As core equipment in heavy industry, the structural design and technological innovation of Nylon industrial conveyor belts directly impact the efficiency and safety of the entire production line.

Nylon industrial conveyor belts generally consist of three components: a cover layer, a tension layer, and a base layer. The cover layer is made of highly wear-resistant rubber, effectively protecting the belt from impact and wear caused by external materials. The tension layer, with its high-strength nylon fiber skeleton, imparts excellent tensile strength and impact resistance. The base layer further enhances the overall belt stability and durability.

Application of New Composite Materials: Utilizing polymer-modified nylon fibers, these belts offer enhanced heat, corrosion, and fatigue resistance, maintaining efficient operation even in high-temperature environments.

Multi-layer Structure Optimization: By strategically stacking multiple layers of nylon fabric and functional rubber, these industrial conveyor belts enhance their flexibility, making them suitable for conveying large spans and high loads.

Intelligent Monitoring Technology: Some high-end products incorporate integrated sensor chips for real-time monitoring of belt temperature, tension, wear, and other data, facilitating early warning and maintenance.

Environmentally Friendly Manufacturing: Utilizing green adhesives, these belts reduce harmful emissions, aligning with sustainable development trends.

Core Application Scenarios for Nylon Industrial Conveyor Belts in Heavy Industry

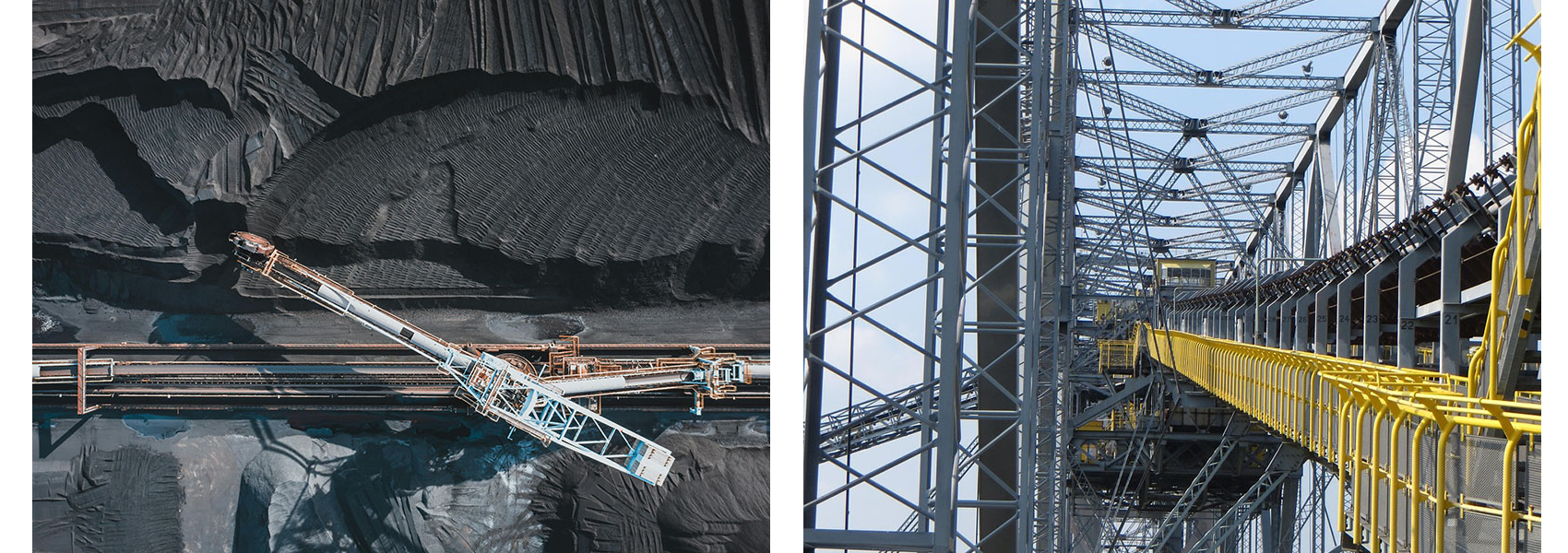

Mining and Coal Industry: Used for long-distance, high-intensity, continuous conveying of bulk materials such as ore and coal. Nylon conveyor belts (industrial conveyor belts) effectively handle high loads, strong impacts, and high temperatures, ensuring stable production line operation.

Steel and Metallurgy Industry: Used for transporting materials such as iron ore and coke in high-temperature, heavy-load environments. Nylon conveyor belts (industrial conveyor belts) are heat-resistant and wear-resistant, significantly extending their service life and reducing the frequency of belt replacement.

Building Materials and Cement Industry: Nylon industrial conveyor belts exhibit excellent wear and corrosion resistance when conveying materials such as cement, sand, gravel, and clinker, making them suitable for dusty and corrosive environments.

Port Logistics: Used in automated conveying systems for bulk cargo, such as containers and bulk cargo, improving loading and unloading efficiency and reducing labor costs.

Chemical Industry: For corrosive materials, the acid, alkali, and oil resistance of Nylon industrial conveyor belts significantly enhances safety and applicability.

Technical Analysis and Selection Guide for Conveyor Belt Rollers and Iron Removers

Conveyor belt rollers serve as the driving force of the conveyor system. Their structure and selection directly impact the efficiency and lifespan of the conveyor belt. Common types of rollers include drive rollers, bend rollers, and tensioning rollers. They are primarily made of high-strength steel and may be coated with rubber to enhance friction and wear resistance.

Technical Highlights:

Precision dynamic balancing design reduces vibration and noise, extending bearing life.

Anti-corrosion surface treatment adapts to high-humidity and highly corrosive environments.

Customizable diameter, length, and rubber coating thickness to meet diverse conveying requirements.

Conveyor belt magnetic separators are critical equipment for ensuring production safety and product purity. Common types include suspension, drum, and tape types. They operate by using a strong magnetic field to attract and separate ferromagnetic impurities from the material, preventing equipment damage and product contamination.

Selection Guide:

Select magnetic field strength and structure based on material characteristics, conveying speed, and impurity content.

Optimize the rare earth alloy NdFeB magnetic source to ensure efficient magnetic removal and long service life.

Automated, maintenance-free design enhances the intelligent level of the production line.

The appropriate configuration of the drum and magnetic separator will significantly improve the efficiency, safety, and economic benefits of the conveying system.

Product Manufacturing Process and Quality Control

The manufacturing process of Nylon industrial conveyor belts determines their performance and lifespan. The main process includes weaving, coating, laminating, vulcanization, cutting, inspection, and packaging.

Weaving: High-strength nylon fibers are precisely woven into a multi-layered fabric base to ensure the belt's tensile strength and flexibility.

Coating: High-performance rubber is evenly applied to the fabric base to enhance wear and corrosion resistance.

Laminating and Vulcanization: The multi-layered fabric base and rubber are bonded together using a high-temperature, high-pressure vulcanization process to ensure interlayer bond strength and overall stability.

Cutting and Inspection: Belts are cut into different specifications according to customer requirements and individually tested for tensile strength, wear resistance, and other properties to ensure 100% product quality before they leave the factory.

Packaging and Transportation: Moisture-proof and impact-resistant packaging is used to ensure product safety during transportation.

For quality control, the company generally adopts international quality management systems such as ISO9001, establishing a full-process quality traceability mechanism from raw material procurement to finished product shipment. The introduction of automated testing equipment and big data analysis has greatly improved product consistency.

Typical Customer Case Studies and Application Records

| Industry | Service |

| Large Coal Mining Enterprise | We provided a high-strength nylon conveyor belt and intelligent roller system to an energy group, enabling efficient long-distance coal transportation, reducing equipment downtime by 30% annually and significantly increasing production capacity. |

| Iron and Steel Metallurgical Enterprise | We customized a high-temperature, wear-resistant nylon conveyor belt and fully automatic iron remover for a steel plant, ensuring stable iron ore transportation in high-temperature environments, significantly improving product purity and equipment life. |

| Port Logistics Center | We provided a large-diameter rubber-coated roller and high-performance iron remover system to a port logistics center, enabling automated container sorting and impurity removal, significantly improving loading and unloading efficiency and safety. |

| Chemical Enterprise | We provided a chemical customer with acid- and alkali-resistant nylon conveyor belts and corrosion-resistant rollers, solving the transportation challenges of corrosive materials, extending equipment life, and reducing maintenance costs. |

| Each case is customized in design and service based on the actual needs of the customer to ensure the best solution and maximum benefits. | |

Maintenance Best Practices

Scientific maintenance is key to extending the service life of nylon conveyor belts and related equipment and ensuring production safety. Recommendations are as follows:

Regular Inspection: Inspect the conveyor belt surface weekly for cracks, wear, deviation, and other signs, and promptly repair or replace damaged areas.

Cleaning and Maintenance: Regularly remove dust and impurities from the belt surface and rollers to prevent localized wear caused by residual material.

Tension Adjustment: Maintain appropriate tension to avoid excessive tension that may cause belt deformation, or excessive looseness that may cause slippage.

Lubrication and Anti-corrosion: Regularly lubricate rotating parts such as roller bearings to prevent rust and seizure.

Abnormal Monitoring: Utilize intelligent sensing devices to monitor key parameters such as temperature and tension in real time, providing timely warnings of abnormal conditions.

Personnel Training: Provide regular professional training to operators and maintenance personnel to enhance maintenance skills and safety awareness.

Through standardized and intelligent maintenance management, equipment failure rates and maintenance costs can be significantly reduced, ensuring efficient and stable operation of the production line.

Solving Common Industry Challenges

Heavy industry customers commonly face pain points such as durability, easy damage, high levels of impurities, and difficult maintenance. We offer one-stop, customized solutions focused on high-strength nylon industrial conveyor belts, intelligent rollers, and efficient iron removers. Through technological innovation and comprehensive quality control, we help customers achieve efficient, safe, and cost-effective production, truly saving them time, money, and effort, and enabling them to stand out in the fiercely competitive market.